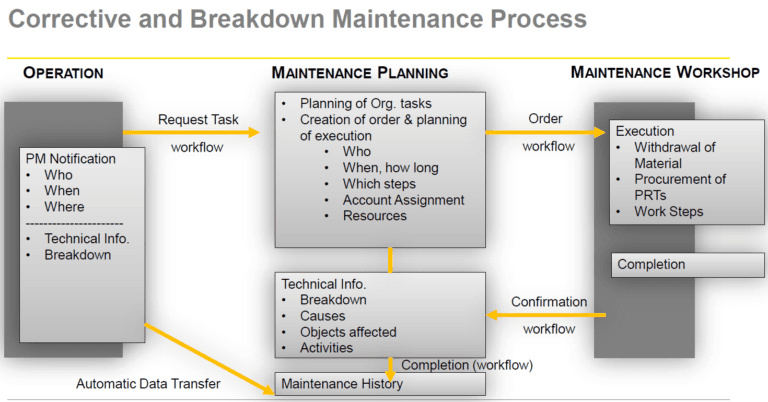

Breakdown maintenance is an essential aspect of any maintenance program that aims to keep equipment and machinery running smoothly. A breakdown maintenance flow chart is a visual representation of the steps involved in responding to equipment failures and malfunctions promptly and effectively.

When a breakdown occurs, the first step is to identify the issue. This may involve observing the equipment, conducting tests, or consulting with operators and maintenance personnel. The breakdown maintenance flow chart helps streamline this process by providing a clear roadmap for diagnosing the problem efficiently.

Breakdown Maintenance Flow Chart

Planning and Execution

Once the issue has been identified, the next step is to plan and execute the necessary repairs. The breakdown maintenance flow chart outlines the steps involved in sourcing spare parts, assigning tasks to maintenance personnel, and scheduling downtime for repairs. By following the flow chart, maintenance teams can ensure that repairs are completed swiftly and with minimal disruption to operations.

Preventative Measures

In addition to responding to breakdowns, a breakdown maintenance flow chart can also help identify recurring issues and implement preventative measures to reduce the likelihood of future breakdowns. By analyzing data from past breakdowns and maintenance activities, maintenance teams can identify trends and proactively address potential issues before they escalate.