Cables are an essential component in various industries, including telecommunications, electronics, and power distribution. The manufacturing process of cables involves several intricate steps that ensure the quality and reliability of the final product. One of the key tools used in the cable manufacturing process is the flow chart, which provides a visual representation of the steps involved in producing cables.

Understanding the cable manufacturing process flow chart is crucial for manufacturers to optimize their production efficiency and quality control. In this article, we will delve into the intricacies of cable manufacturing and explore the various steps involved in creating high-quality cables.

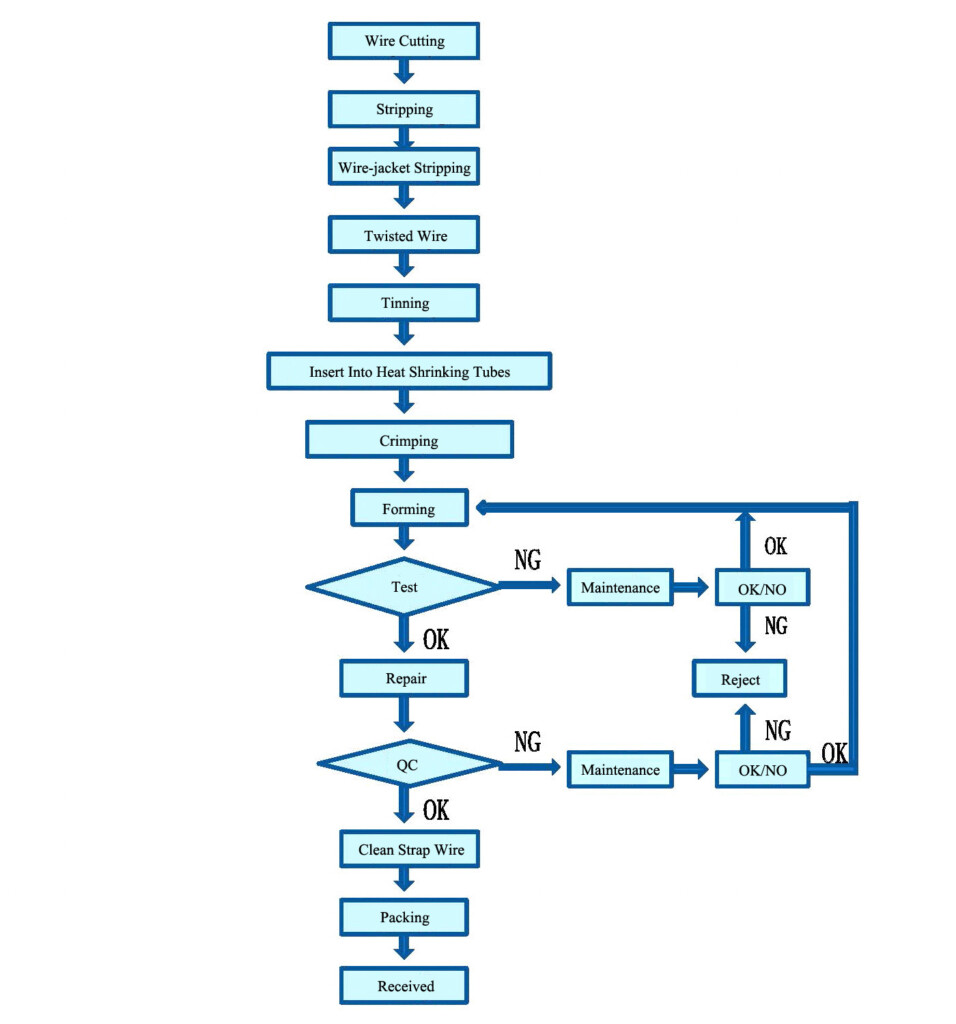

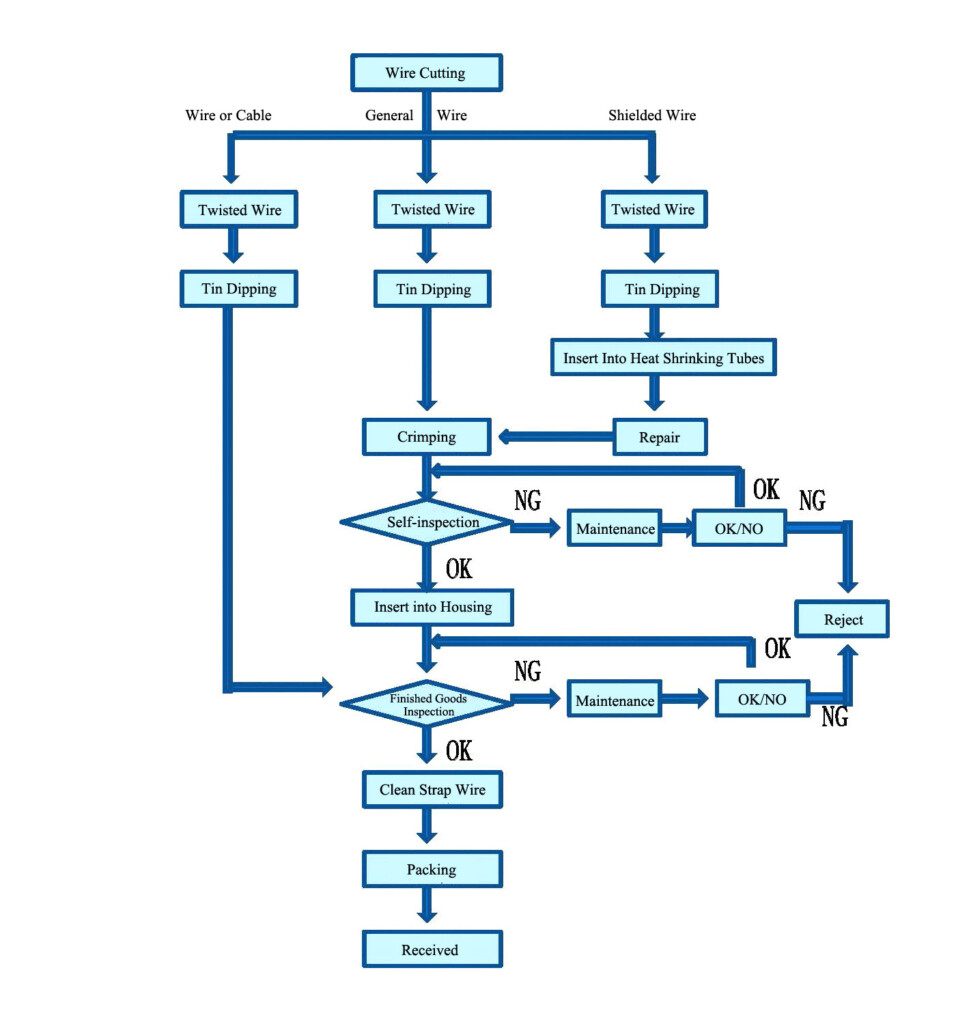

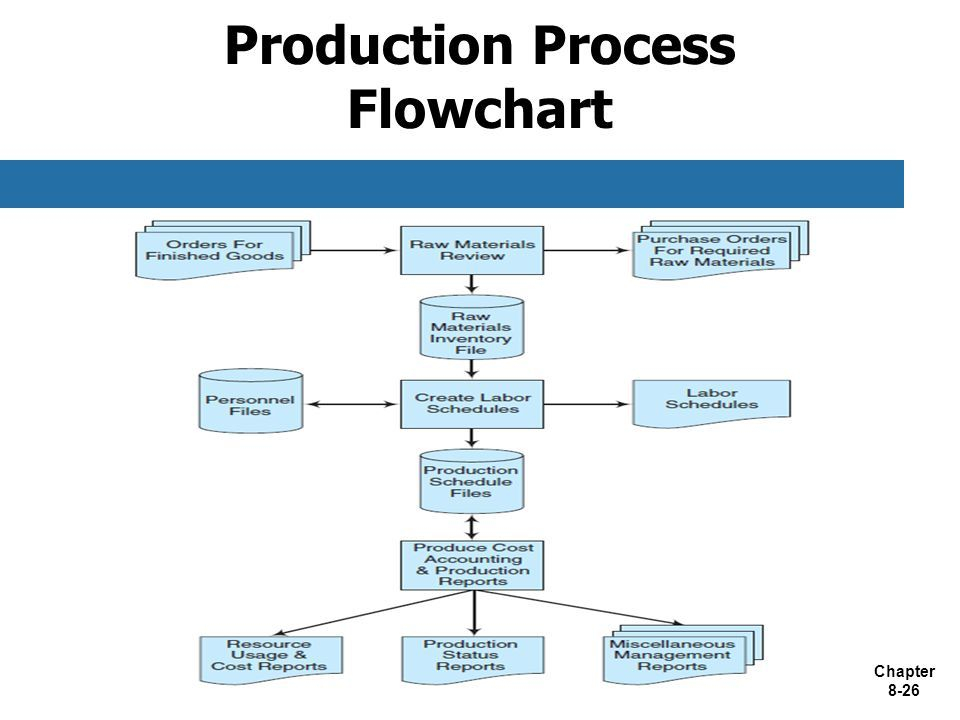

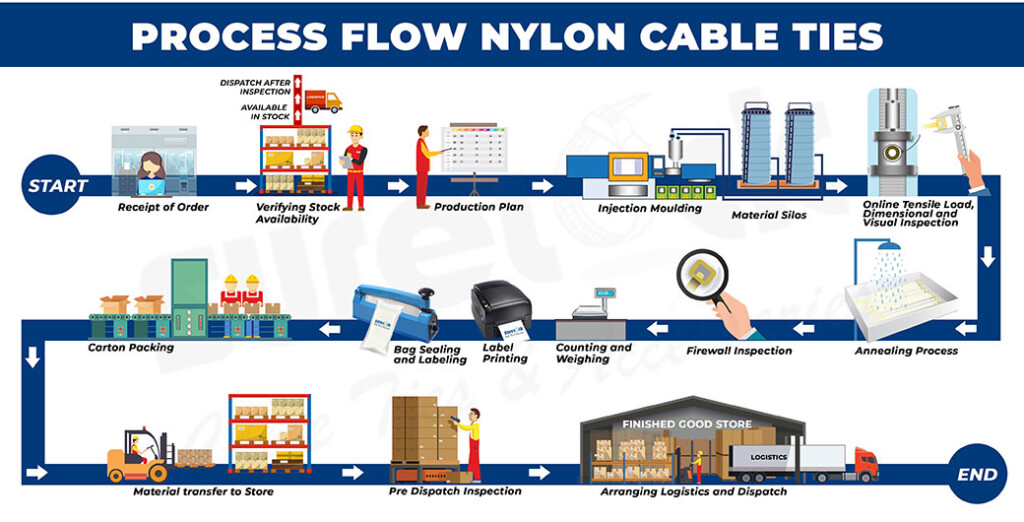

Cable Manufacturing Process Flow Chart

Extrusion Process

The extrusion process is a fundamental step in cable manufacturing, where raw materials such as PVC, polyethylene, or rubber are melted and forced through a die to form the cable’s core. The extruded core is then passed through a cooling system to solidify the material before being coated with additional layers, such as insulation and sheathing. The extrusion process plays a crucial role in determining the cable’s electrical properties, mechanical strength, and overall performance.

Once the core is extruded and coated with insulation and sheathing layers, it undergoes a series of quality control tests to ensure compliance with industry standards and specifications. These tests may include measuring the thickness and uniformity of the insulation layers, conducting electrical conductivity tests, and checking for any defects or imperfections in the cable structure. The extrusion process is a critical step in cable manufacturing, as it directly impacts the cable’s performance and durability.

Assembly and Testing

After the extrusion process is complete, the cables are assembled into their final configurations, such as twisted pairs, coaxial cables, or multi-conductor cables. The assembled cables are then subjected to rigorous testing to ensure their functionality and reliability. Testing procedures may include measuring electrical conductivity, insulation resistance, and signal transmission capabilities. Any cables that fail to meet the specified standards are either reworked or rejected to maintain the quality of the final product.

Once the cables have passed the testing phase, they are carefully packaged and prepared for shipping to customers. The cable manufacturing process flow chart provides a visual roadmap of the entire production process, from raw material preparation to final product assembly and testing. By following the flow chart, manufacturers can streamline their operations, improve quality control, and deliver high-quality cables that meet the needs of their customers.

In conclusion, understanding the cable manufacturing process flow chart is essential for manufacturers to produce high-quality cables efficiently and effectively. By following the steps outlined in the flow chart, manufacturers can ensure the consistency and reliability of their products, ultimately leading to customer satisfaction and business success.

Download Cable Manufacturing Process Flow Chart

Cable Manufacturing Process Flow Chart

Cable Manufacturing Process Flow Chart

Cable Manufacturing Process Flow Chart

Cable Manufacturing Process Flow Chart