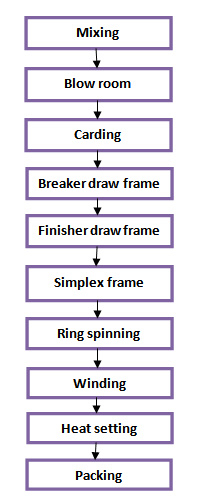

Carded yarn is a type of yarn that is produced through a process known as carding, which involves aligning and blending fibers to create a smooth and consistent yarn. The carded yarn flow chart is a visual representation of the various steps involved in producing carded yarn, from the initial blending of fibers to the final spinning of the yarn. By understanding the carded yarn flow chart, you can gain insight into the intricate process of creating high-quality carded yarn.

The first step in the carded yarn flow chart is the blending process, where different types of fibers are mixed together to create a uniform blend. This is typically done using a carding machine, which combs and aligns the fibers to ensure a consistent mix. The blending process is crucial in creating yarn with the desired characteristics, such as strength, softness, and color. Once the fibers are blended, they are ready to move on to the next step in the carded yarn flow chart.

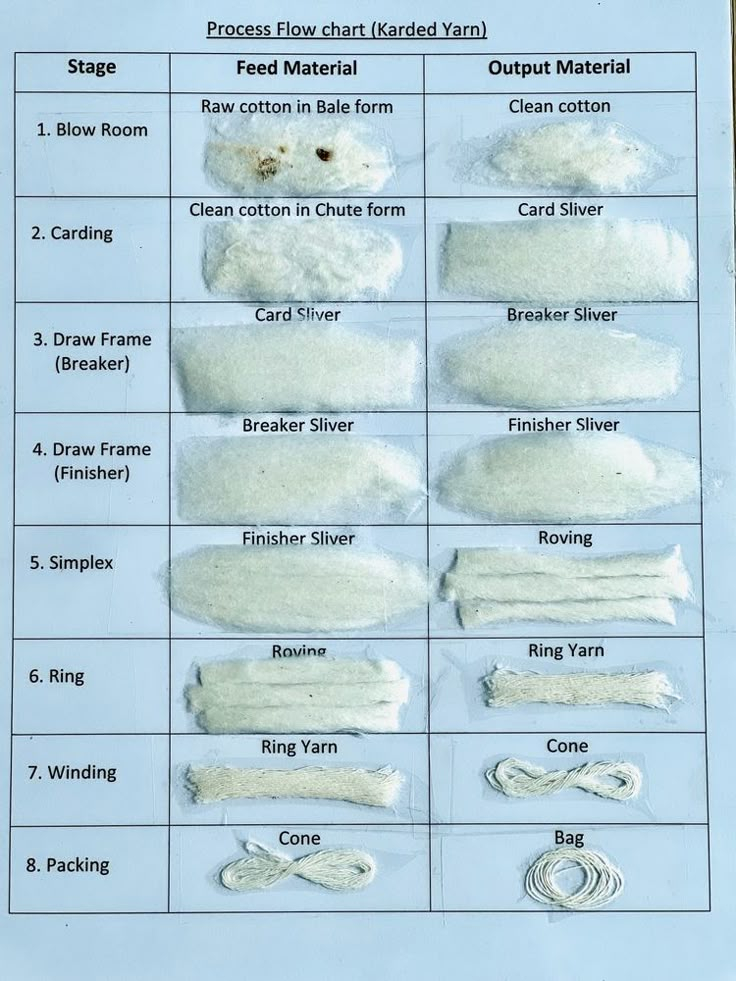

Carded Yarn Flow Chart

The Carding Process

After the fibers have been blended, they move on to the carding process, where they are further aligned and cleaned to prepare them for spinning. This step involves passing the fibers through a series of rollers and wire brushes, which comb and straighten the fibers to create a smooth and even yarn. The carding process is essential in ensuring that the yarn is of high quality and free from any impurities or irregularities. Once the fibers have been carded, they are ready to move on to the final step in the carded yarn flow chart.

The Spinning Process

The final step in the carded yarn flow chart is the spinning process, where the carded fibers are twisted together to create the final yarn. This step involves passing the carded fibers through a spinning machine, which twists the fibers together to create a strong and durable yarn. The spinning process can be adjusted to create yarn with different characteristics, such as thickness, strength, and texture. Once the yarn has been spun, it is ready to be dyed, finished, and prepared for use in various textile applications.

In conclusion, the carded yarn flow chart provides a detailed overview of the intricate process involved in producing high-quality carded yarn. By understanding the various steps in the carded yarn flow chart, you can gain insight into the art and science of creating yarn that meets the highest standards of quality and consistency.

Download Carded Yarn Flow Chart

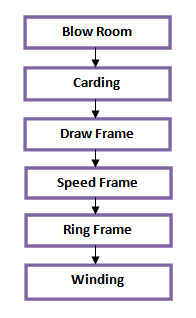

Carded Yarn Manufacturing Process ORDNUR

Carded Yarn Manufacturing Process ORDNUR

Carded Yarn Manufacturing Process ORDNUR

The Carding Process From Fiber To Yarn