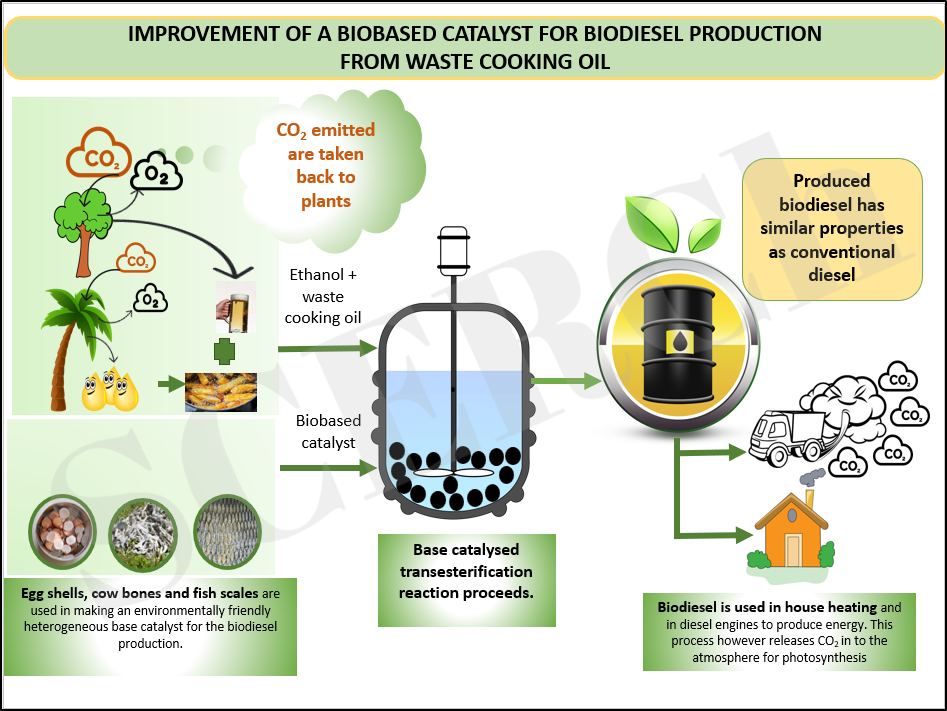

Biodiesel is a renewable fuel that is produced from vegetable oils or animal fats. The production process involves several steps that are essential for converting these raw materials into a usable fuel source. A flow chart of biodiesel production outlines the key stages involved in this process, from feedstock selection to the final product.

One of the primary benefits of biodiesel production is its environmental sustainability. Biodiesel is a cleaner-burning fuel compared to traditional petroleum diesel, making it a popular choice for reducing greenhouse gas emissions and air pollution. Understanding the flow chart of biodiesel production is crucial for ensuring efficient and cost-effective production methods.

Flow Chart Of Biodiesel Production

Feedstock Selection

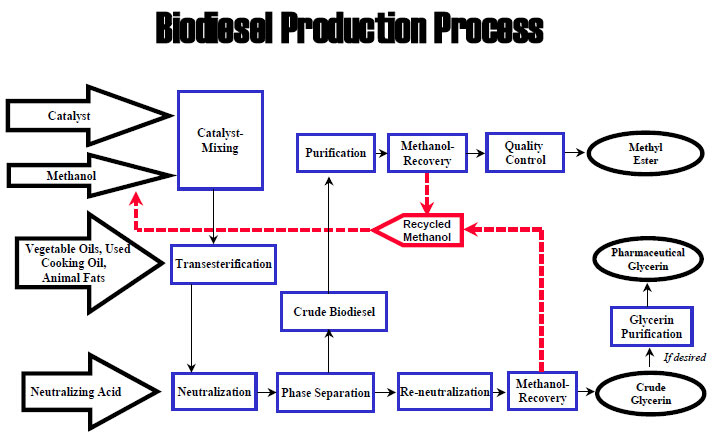

The first step in biodiesel production is selecting a suitable feedstock, such as soybean oil, canola oil, or animal fats. The chosen feedstock must contain a high percentage of triglycerides, which are essential for the transesterification process. The quality and purity of the feedstock directly impact the final quality of the biodiesel product.

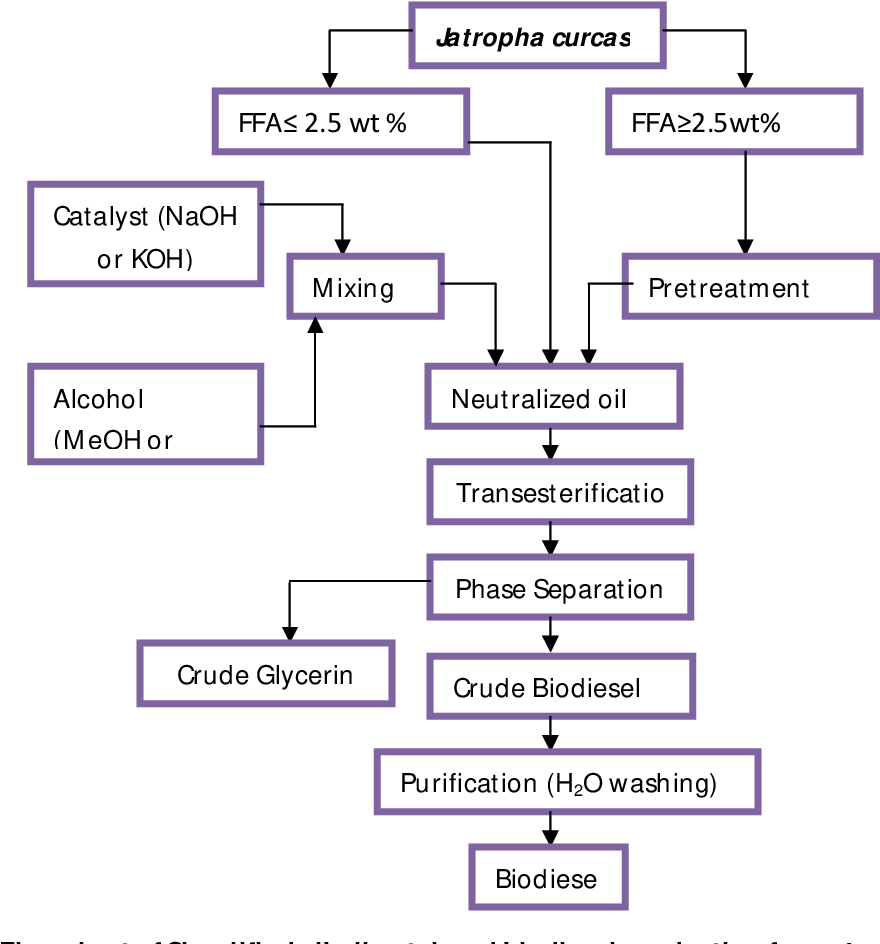

Once the feedstock is selected, it undergoes a series of pre-treatment processes to remove impurities and contaminants. This includes filtering, heating, and drying the feedstock to ensure optimal conditions for the transesterification reaction. Proper feedstock selection and pre-treatment are critical for producing high-quality biodiesel with consistent performance.

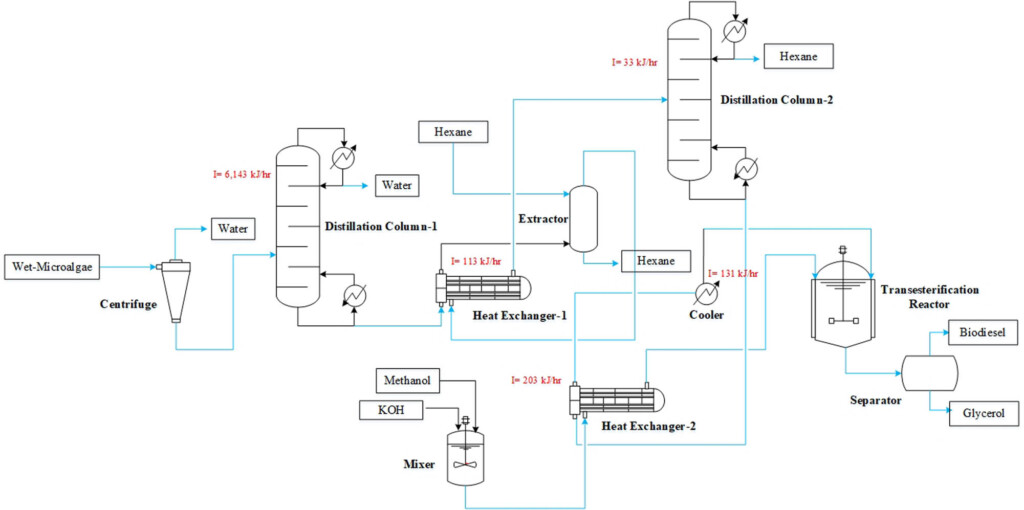

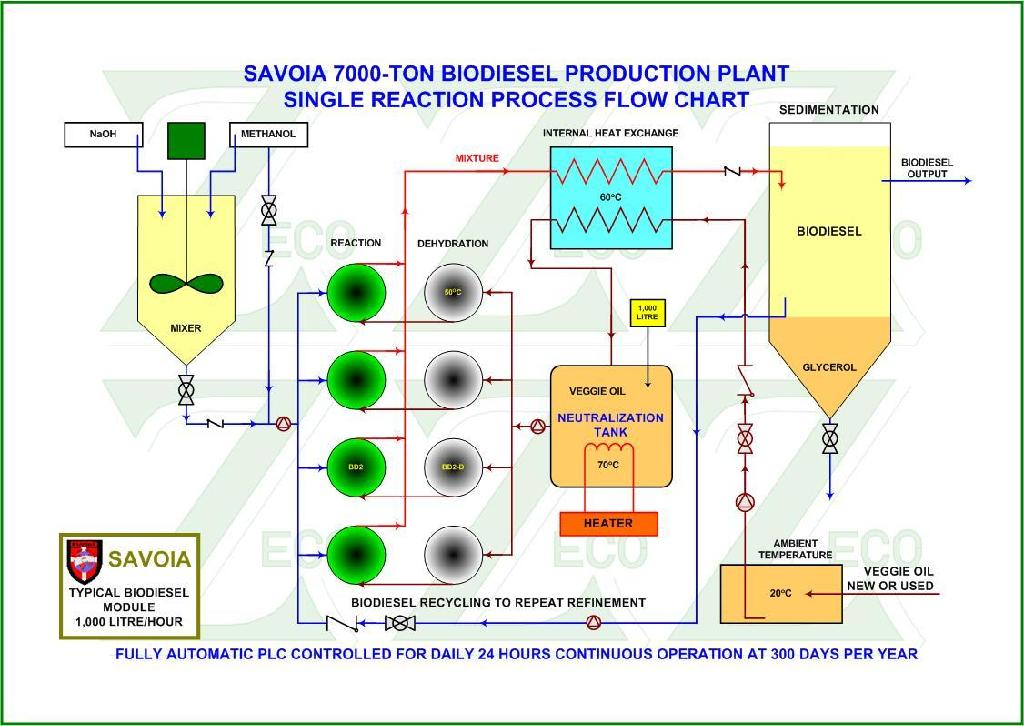

Transesterification Process

The transesterification process is the key step in biodiesel production, where the triglycerides in the feedstock are converted into biodiesel and glycerin. This process involves reacting the feedstock with an alcohol, typically methanol or ethanol, and a catalyst, such as sodium hydroxide or potassium hydroxide. The reaction produces biodiesel and glycerin as byproducts.

After the transesterification reaction is complete, the mixture is separated into biodiesel and glycerin using a separation process, such as gravity settling or centrifugation. The biodiesel is then washed and dried to remove any remaining impurities and excess alcohol. The final product is a pure biodiesel fuel that meets industry standards for quality and performance.

Understanding the flow chart of biodiesel production is essential for manufacturers and researchers in the renewable energy industry. By following a systematic approach to biodiesel production, producers can optimize their processes, reduce waste, and improve the overall quality of the final product. With the increasing demand for sustainable fuel sources, biodiesel production plays a crucial role in reducing our reliance on fossil fuels and mitigating the impacts of climate change.

Download Flow Chart Of Biodiesel Production

Biodiesel Production Process Flow Diagram

27 Biofuels Chart Background Engineering 39 s Advice

Biodiesel Production Process Flow Diagram

Biodiesel Production Process Flow Diagram