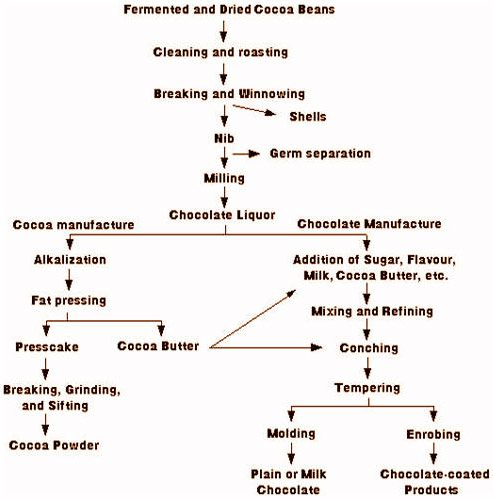

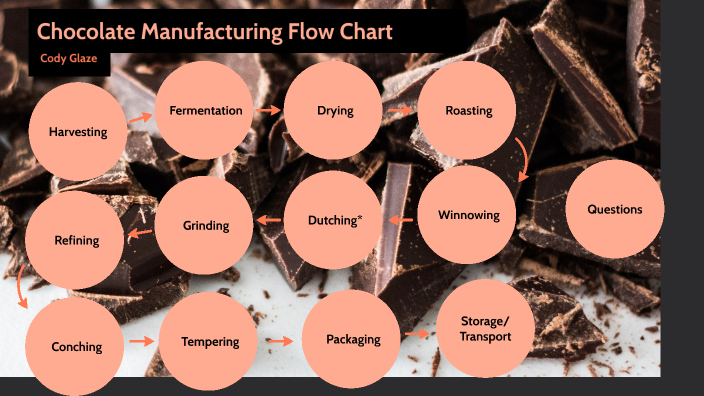

Chocolate production starts with the harvesting of cocoa beans from cocoa trees. The beans are then transported to processing facilities where they undergo fermentation and drying processes. After drying, the cocoa beans are roasted to bring out their rich flavor. The roasted beans are then cracked and winnowed to remove the outer shell, leaving only the cocoa nibs.

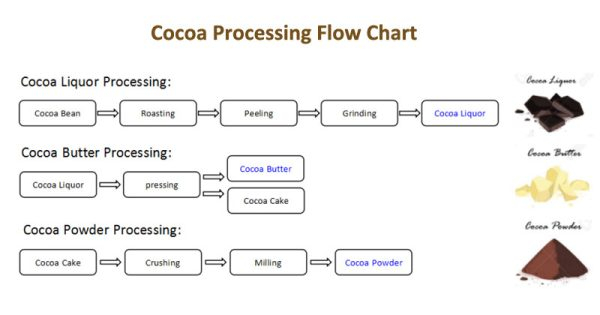

Once the cocoa nibs are obtained, they are ground into a paste known as chocolate liquor. This liquor can then be separated into cocoa solids and cocoa butter through a process called pressing. The cocoa solids are what give chocolate its distinct flavor, while the cocoa butter adds richness and smoothness to the final product.

Flow Chart Of Chocolate Production

2. Mixing and Conching

After obtaining the cocoa solids and cocoa butter, they are mixed together with other ingredients such as sugar, milk powder, and vanilla to create the chocolate mixture. This mixture is then refined through a process called conching, which involves heating and stirring the mixture to develop its flavor and texture. The longer the conching process, the smoother and creamier the chocolate will be.

During conching, any excess moisture and volatile acids are removed, resulting in a more refined and balanced chocolate flavor. This step is crucial in ensuring the quality of the final product and can greatly impact the overall taste and texture of the chocolate.

3. Tempering and Molding

Once the chocolate mixture has been conched to perfection, it is tempered to ensure a smooth and glossy finish. Tempering involves carefully heating and cooling the chocolate to specific temperatures to stabilize the cocoa butter crystals and prevent the formation of dull, streaky spots on the chocolate’s surface.

Finally, the tempered chocolate is poured into molds and allowed to cool and solidify. After the chocolate has set, it can be removed from the molds and packaged for distribution. The entire process of chocolate production, from harvesting cocoa beans to molding the final product, requires precision and expertise to create high-quality chocolates that are enjoyed by chocolate lovers around the world.

By following the flow chart of chocolate production, chocolate manufacturers can ensure that each step is carefully executed to produce delicious and decadent chocolates that satisfy even the most discerning palates.

Download Flow Chart Of Chocolate Production

Flow Chart For Cocoa Processing Download Scientific D Vrogue co

Cocoa Processing Flow Chart From Bean To Powder Cocoa Machinery

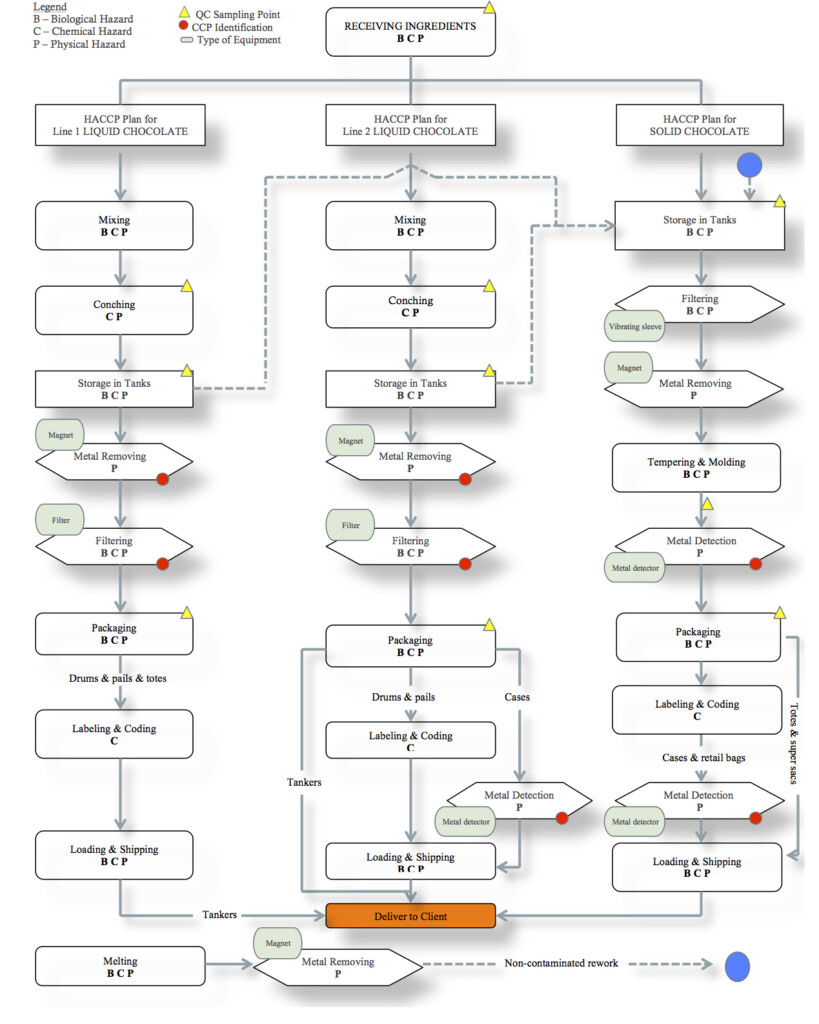

Chocolate Process Flow Diagram And HACCP Plan

Chocolate Manufacturing Flow Chart By Cody On Prezi