One of the first steps in the door manufacturing process is the selection of materials. The type of material chosen will depend on the desired appearance, durability, and cost of the door. Common materials used for doors include wood, metal, and fiberglass. Once the material is selected, it is cut into the appropriate size and shape for the door being manufactured.

After the material is cut, it is then treated to prevent rotting, warping, or other damage. This may involve applying a sealant, paint, or stain to the surface of the door. The material is then left to dry before moving on to the next step in the manufacturing process.

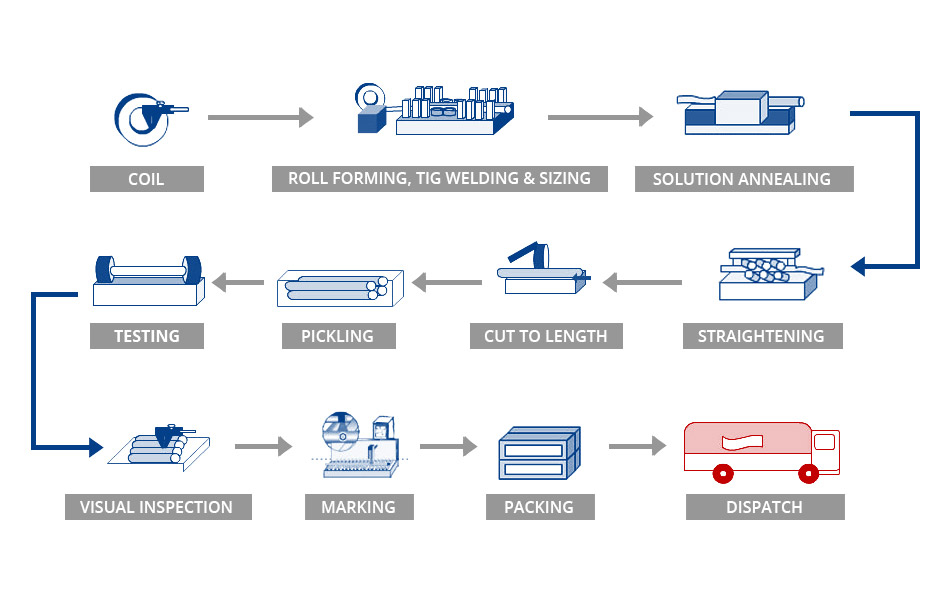

Door Manufacturing Process Flow Chart

2. Assembly and Construction

Once the material has been prepared, it is time to assemble and construct the door. This may involve joining multiple pieces of material together using screws, nails, or adhesives. The door frame is typically assembled first, followed by the addition of panels, glass, or other decorative elements.

During the assembly process, quality control checks are performed to ensure that the door meets the necessary standards for strength, durability, and appearance. Any defects or imperfections are corrected before the door moves on to the next stage of manufacturing.

3. Finishing and Inspection

After the door has been assembled and constructed, it is then finished and inspected. This may involve sanding the surface of the door to create a smooth finish, applying a final coat of paint or stain, and adding any necessary hardware such as handles, locks, or hinges.

Once the finishing touches have been applied, the door undergoes a final inspection to ensure that it meets all quality standards. Any necessary adjustments or repairs are made before the door is packaged and prepared for shipping to its final destination.