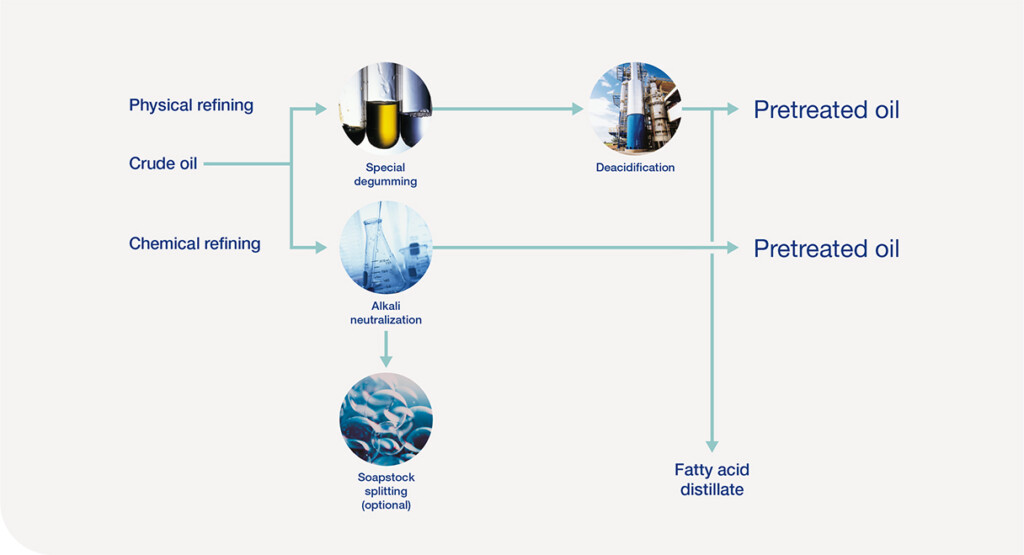

Before biodiesel can be produced, the feedstock, which is usually vegetable oils or animal fats, needs to be prepared. This involves filtering the feedstock to remove any impurities or solid particles that could clog the processing equipment. The feedstock is then heated to reduce its viscosity, making it easier to process.

Once the feedstock is prepared, it is ready to undergo transesterification, the chemical process that converts the feedstock into biodiesel.

Biodiesel Process Flow Chart

Transesterification

Transesterification is the key step in the production of biodiesel. In this process, the feedstock is mixed with an alcohol, usually methanol or ethanol, and a catalyst, typically sodium hydroxide or potassium hydroxide. The mixture is then heated and stirred for a specific period of time to allow the chemical reaction to take place.

During transesterification, the ester bonds in the feedstock are broken and replaced with alcohol molecules, resulting in the production of biodiesel and glycerin as a byproduct. The glycerin is separated from the biodiesel and can be used in various other industries.

Biodiesel Refinement

After transesterification, the biodiesel undergoes a refining process to remove any remaining impurities and excess alcohol. This can involve washing the biodiesel with water to remove any residual catalyst or impurities. The biodiesel is then dried to remove any remaining water before it is ready for use.

Once the biodiesel has been refined, it is ready to be used as a renewable and environmentally friendly alternative to traditional diesel fuel.