CMOS (Complementary Metal-Oxide-Semiconductor) is a technology used in the manufacturing of integrated circuits. The CMOS fabrication process flow chart is a visual representation of the steps involved in creating CMOS devices. It outlines the various stages from designing the circuit to the final testing of the chip.

The fabrication process begins with the design of the circuit layout using specialized software. This layout is then transferred onto a silicon wafer through a series of photolithography steps. The wafer is then processed through various stages of deposition, etching, and doping to create the intricate structures required for the functioning of the CMOS devices.

Cmos Fabrication Process Flow Chart

Key Steps in the CMOS Fabrication Process Flow Chart

The CMOS fabrication process flow chart typically includes the following key steps:

- Design Layout: The circuit design is created using CAD software.

- Wafer Preparation: The silicon wafer is cleaned and prepared for processing.

- Photolithography: The circuit layout is transferred onto the wafer using photoresist and light exposure.

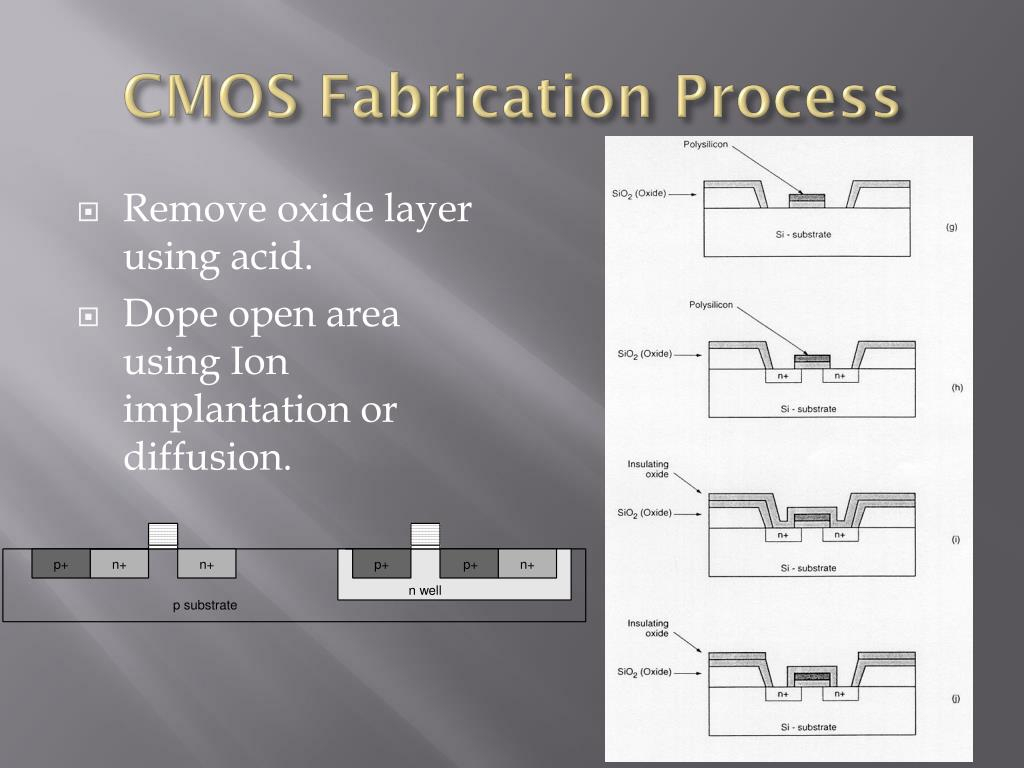

- Etching: Unwanted materials are removed from the wafer using chemical etching.

- Doping: Dopants are added to the wafer to modify its electrical properties.

- Metal Deposition: Metal layers are deposited onto the wafer to create interconnects.

- Oxidation: The wafer is oxidized to create insulating layers.

- Cleaning and Testing: The final chip is cleaned, tested, and packaged for distribution.

Conclusion

The CMOS fabrication process flow chart provides a detailed overview of the complex manufacturing process involved in creating CMOS devices. By following this structured approach, manufacturers can ensure the quality and reliability of their integrated circuits. Understanding the key steps in the fabrication process is crucial for optimizing the performance and functionality of CMOS devices in various electronic applications.