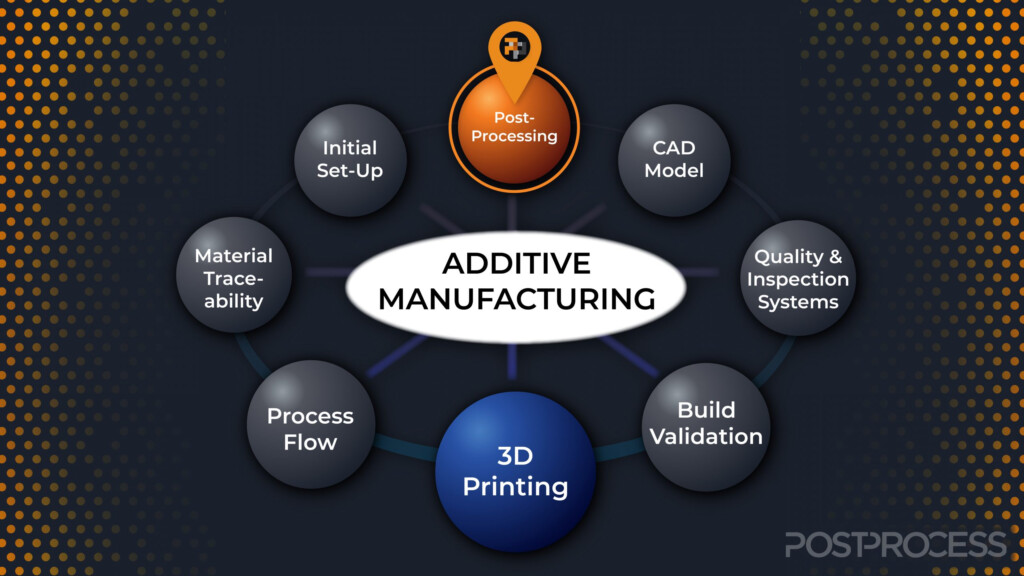

Additive manufacturing, also known as 3D printing, is a revolutionary technology that allows for the creation of complex three-dimensional objects layer by layer. This process is in stark contrast to traditional manufacturing methods that involve subtractive techniques, where material is removed to create the desired shape. Additive manufacturing offers numerous benefits, including cost-effectiveness, faster production times, and the ability to create intricate designs that would be impossible with traditional methods.

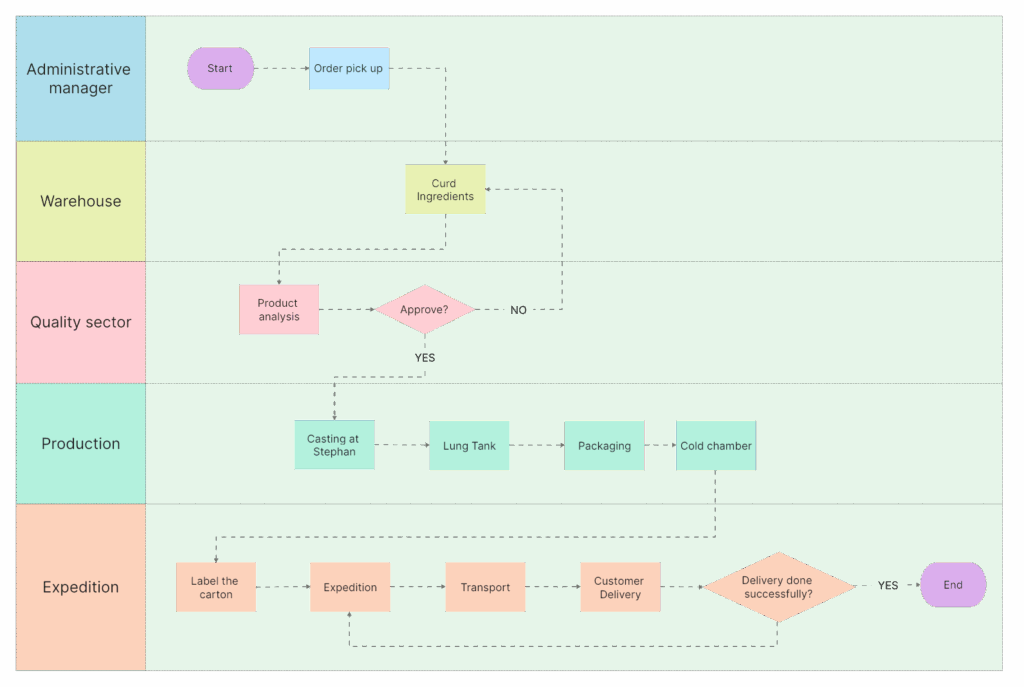

One of the key components of additive manufacturing is the use of a flow chart to guide the process from design to final product. This flow chart outlines the steps involved in each stage of production, ensuring that each layer is deposited accurately and efficiently. By following a well-designed additive manufacturing flow chart, manufacturers can streamline their production process and achieve optimal results.

Additive Manufacturing Flow Chart

Benefits of Using an Additive Manufacturing Flow Chart

There are several advantages to using an additive manufacturing flow chart in the production process. Firstly, a flow chart helps to visualize the entire manufacturing process, allowing for better planning and organization. This ensures that each step is carried out in the correct sequence, minimizing errors and reducing production time.

Additionally, an additive manufacturing flow chart can help identify potential bottlenecks or inefficiencies in the production process. By analyzing the flow chart, manufacturers can pinpoint areas that may need improvement and make adjustments to optimize the workflow. This proactive approach can lead to increased efficiency, cost savings, and higher quality finished products.

Creating an Effective Additive Manufacturing Flow Chart

When creating an additive manufacturing flow chart, it is important to consider the specific requirements of the production process. Each step should be clearly defined, with detailed instructions on how to execute the task. It is also essential to include checkpoints and quality control measures to ensure that each layer meets the desired specifications.

Collaboration between design engineers, production managers, and operators is crucial in developing an effective additive manufacturing flow chart. By involving all stakeholders in the process, manufacturers can create a flow chart that accurately reflects the production workflow and addresses any potential issues that may arise. Regular updates and revisions to the flow chart can help to continuously improve the production process and adapt to changing requirements.

In conclusion, an additive manufacturing flow chart is a valuable tool for optimizing the production process and achieving superior results. By carefully designing and implementing a well-structured flow chart, manufacturers can streamline their operations, reduce costs, and produce high-quality products efficiently.

Download Additive Manufacturing Flow Chart

Additive Manufacturing Techniques

Mastering Manufacturing Flow Charts A Step by Step Guide

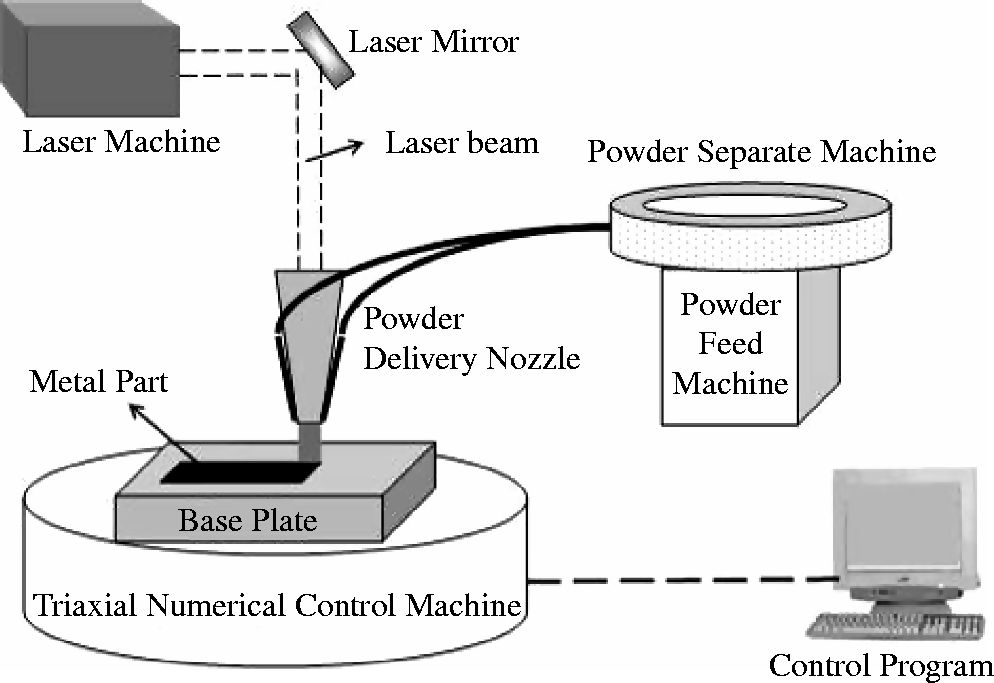

Additive Manufacturing Laser diagram 2 CAFE Foundation Blog

Additive Manufacturing Flow Chart