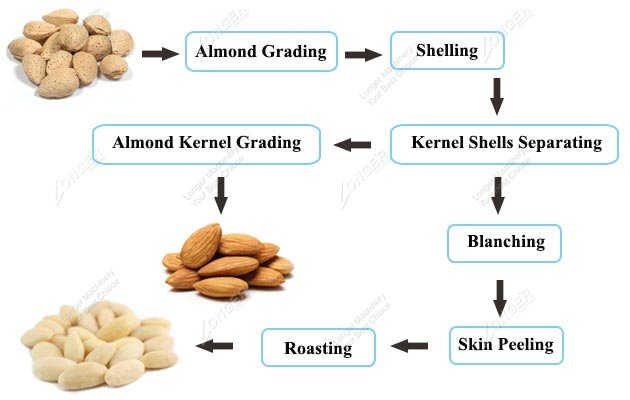

The first step in the almond milk processing flow chart is soaking the almonds in water for a period of time, usually overnight. This helps to soften the almonds and make them easier to blend. Once the almonds have been soaked, they are drained and rinsed before being blended with fresh water. The ratio of almonds to water will depend on the desired consistency of the almond milk.

After blending, the mixture is strained through a nut milk bag or cheesecloth to remove any solid pieces of almond. The resulting liquid is the almond milk base, which can be flavored with vanilla, sweetened with dates or maple syrup, or left plain.

Almond Milk Processing Flow Chart

Step 2: Pasteurization and Homogenization

After the almond milk base has been prepared, it is pasteurized to kill any harmful bacteria and extend the shelf life of the product. Pasteurization involves heating the almond milk to a specific temperature for a set amount of time before rapidly cooling it. This process helps to ensure the safety of the almond milk for consumption.

In some cases, the almond milk may also undergo homogenization, which breaks down the fat molecules in the liquid to create a more consistent texture. This step is optional and can be skipped depending on the desired final product.

Step 3: Packaging and Distribution

Once the almond milk has been pasteurized and homogenized (if necessary), it is ready to be packaged and distributed to consumers. The almond milk is typically poured into cartons or bottles, sealed, and labeled with the necessary information such as expiration date, ingredients, and nutritional content.

From there, the almond milk is shipped to retailers or directly to consumers for purchase. Some companies may also offer almond milk in bulk quantities for use in commercial food production or food service settings.

By following this almond milk processing flow chart, producers can create a high-quality product that is safe for consumption and meets the needs of consumers looking for a dairy-free alternative. Whether you’re a small-scale producer or a large manufacturer, understanding the steps involved in almond milk processing is essential for creating a successful product.

Download Almond Milk Processing Flow Chart

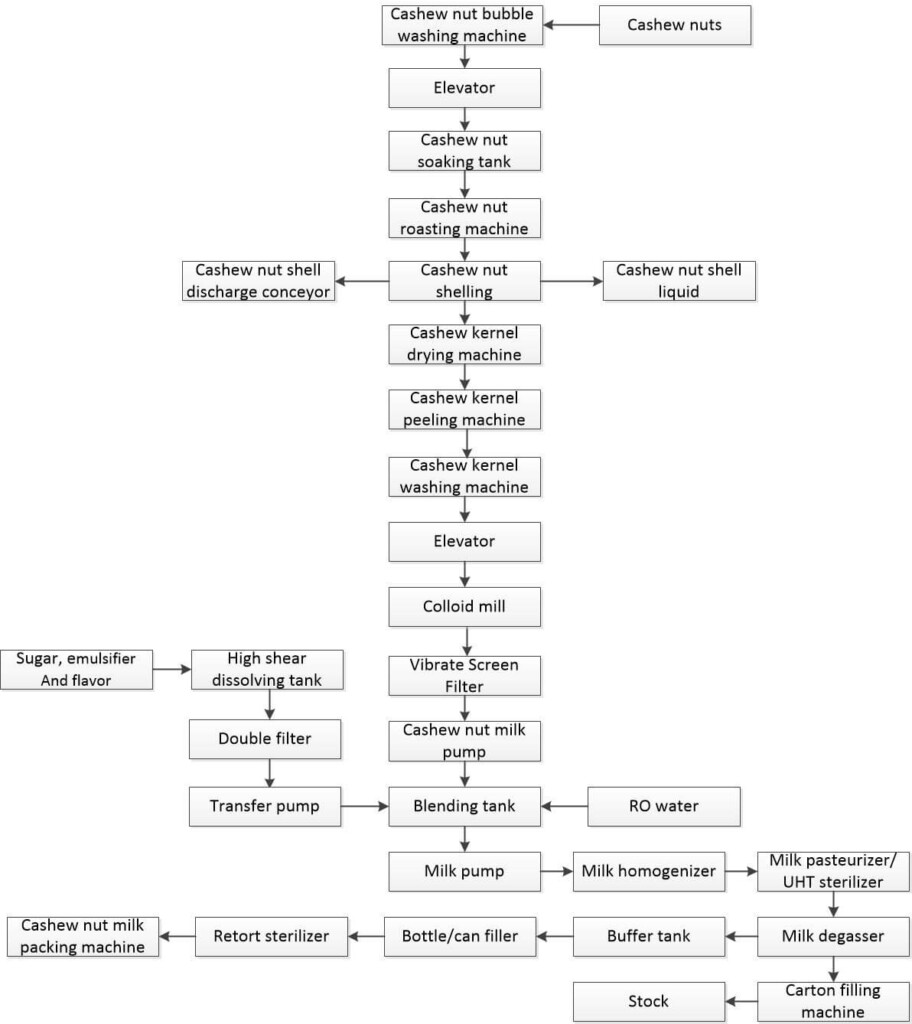

Cashew Nut Processing Flow Chart

Cashew Nut Processing Flow Chart

UHT Milk Processing Machine Uht Milk Processing Steps Uht Milk

13 Milk Processing Flow Chart Robhosking Diagram