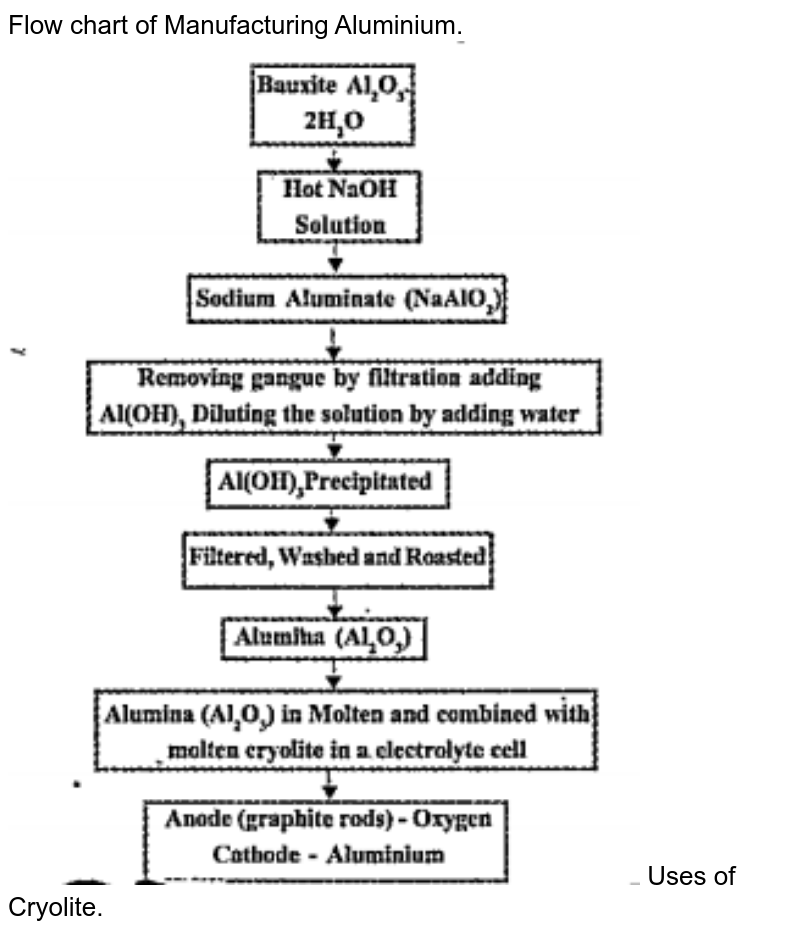

Aluminium is a versatile and widely used metal in various industries due to its lightweight, corrosion-resistant, and recyclable properties. The aluminium manufacturing process involves several steps from bauxite ore extraction to the final product. A flow chart helps visualize these steps efficiently.

The first step in the aluminium manufacturing process is the extraction of bauxite, which is the primary source of aluminium. Bauxite is mined in open-pit mines and refined to extract alumina through the Bayer process. Alumina is then smelted using electrolysis to produce pure aluminium.

Aluminium Process Flow Chart

Aluminium Smelting

Aluminium smelting is a crucial step in the production process. The alumina obtained from bauxite is dissolved in molten cryolite and electrolyzed to separate oxygen and aluminium. This process requires a significant amount of electricity, making aluminium production energy-intensive.

Casting and Fabrication

After the aluminium is smelted, it is cast into ingots or billets for further processing. These raw forms of aluminium can then be fabricated into various products through processes like extrusion, rolling, or forging. The final products can range from simple household items to complex aerospace components.