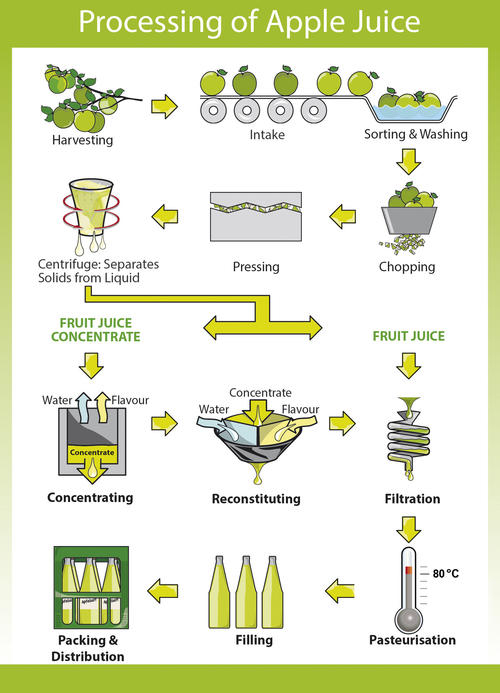

First, ripe apples are harvested from orchards and transported to the processing facility. The apples are then washed thoroughly to remove any dirt, debris, and pesticides. This step is crucial to ensure that only clean and safe apples are used in the juice production process.

Once the apples are washed, they are sorted based on their quality and size. This helps in ensuring a consistent taste and quality of the final apple juice product. After sorting, the apples are crushed or pulped to extract the juice.

Apple Juice Processing Flow Chart

Extraction and Filtration

The extracted juice is then filtered to remove any solid particles and impurities. This process helps in obtaining a clear and smooth apple juice. The filtered juice is then pasteurized to kill any harmful bacteria and enzymes that may affect the shelf life of the juice.

After pasteurization, the apple juice is concentrated through a process called evaporation. This helps in reducing the water content in the juice, making it more concentrated and flavorful. Finally, the concentrated juice is cooled and packaged into bottles or cartons for distribution to consumers.

Conclusion

Understanding the apple juice processing flow chart is essential for anyone involved in the production and distribution of this popular beverage. By following these steps carefully, manufacturers can ensure that the apple juice produced is of high quality and safe for consumption. So next time you enjoy a glass of apple juice, you can appreciate the intricate process that goes into making it.