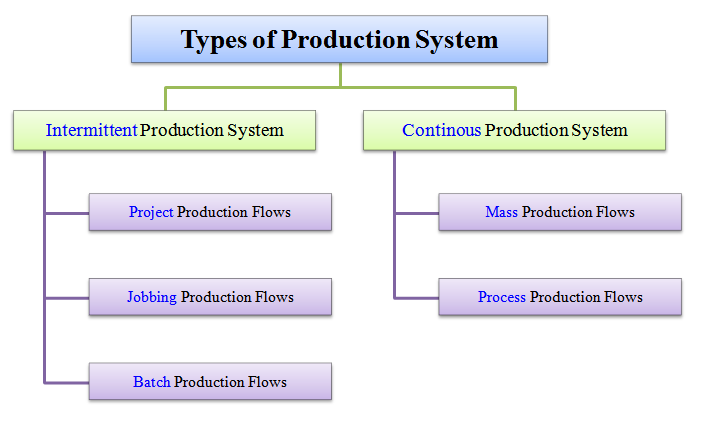

A batch production flow chart is a visual representation of the manufacturing process that breaks down the production steps into sequential order. It helps streamline production, improve efficiency, and ensure consistency in quality. By outlining each step of the production process, from raw materials to finished products, a batch production flow chart allows manufacturers to identify potential bottlenecks, optimize resources, and monitor progress.

Batch production flow charts typically include information such as the quantity of raw materials needed, the time required for each production step, quality control checkpoints, and the final product specifications. This visual tool provides a clear overview of the entire production process, making it easier for managers and workers to coordinate their efforts and keep production on track.

Batch Production Flow Chart

Benefits of Using a Batch Production Flow Chart

There are several benefits to using a batch production flow chart in manufacturing processes. Firstly, it helps in identifying inefficiencies and bottlenecks in the production process, allowing for quick adjustments to improve productivity. Secondly, it ensures consistency in product quality by standardizing production steps and quality control measures. Thirdly, it helps in estimating production costs and timelines, enabling better resource planning and budgeting.

Moreover, batch production flow charts promote better communication and coordination among team members by providing a visual reference for the entire production process. This leads to improved collaboration and faster decision-making. Lastly, by documenting the production process in a clear and structured manner, batch production flow charts serve as valuable training tools for new employees, ensuring that they understand the workflow and quality standards.

Implementing a Batch Production Flow Chart

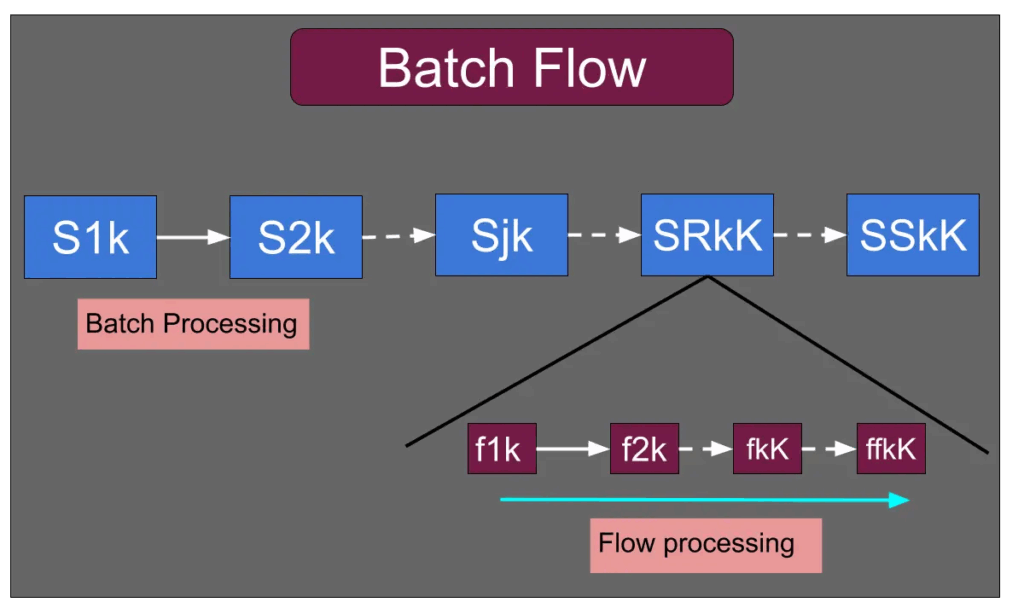

To create a batch production flow chart, start by identifying the key production steps and their sequence. Gather information on the materials, equipment, and personnel required for each step. Use flowchart symbols and arrows to represent the flow of materials and activities from one step to the next. Include quality control checkpoints and any necessary feedback loops to ensure product quality.

Once the batch production flow chart is created, regularly review and update it to reflect any changes in the production process or new insights gained from production data. Use the flow chart as a reference tool during production meetings and training sessions to ensure that everyone is on the same page. By implementing a batch production flow chart, manufacturers can optimize their production processes, enhance product quality, and improve overall efficiency.

By following these steps and guidelines, manufacturers can effectively utilize batch production flow charts to streamline their production processes and achieve greater success in the competitive manufacturing industry.

Download Batch Production Flow Chart

Batch And Jobshop Production Management Guru Management Guru

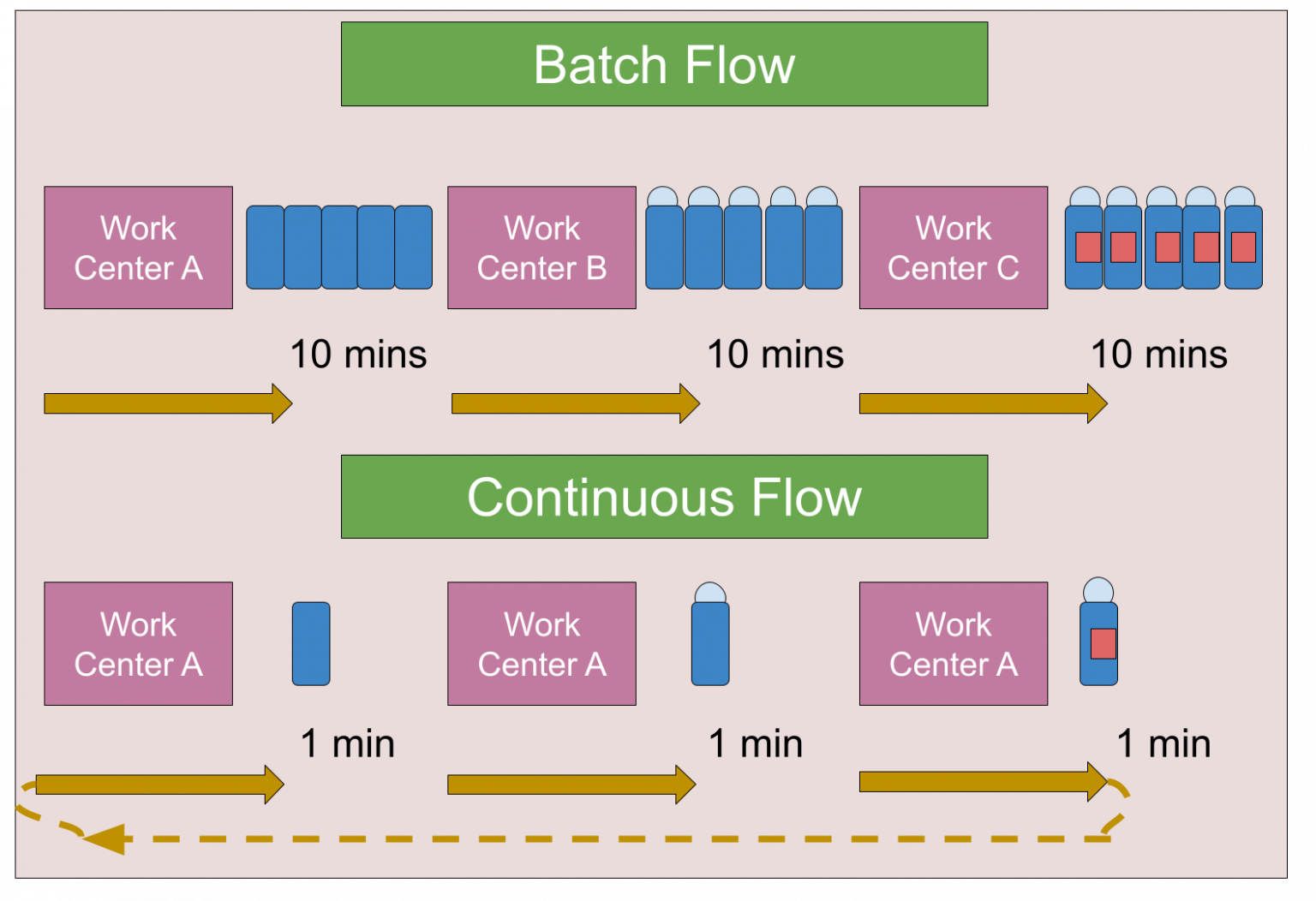

What Is Batch Flow Continuous Flow And Alternatives

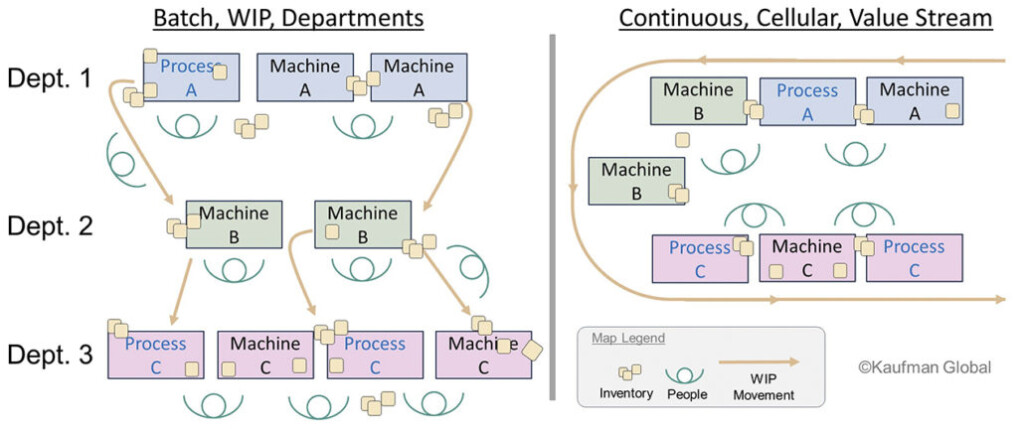

Batch Production Kaufman Global Large Lot Production