Blister packaging is a popular method of packaging products in a transparent plastic cavity sealed to a backing card. This type of packaging is commonly used for pharmaceuticals, consumer goods, and electronics to protect the product and provide visibility to consumers. The blister packaging process involves several steps that are crucial to ensuring the quality and integrity of the final product.

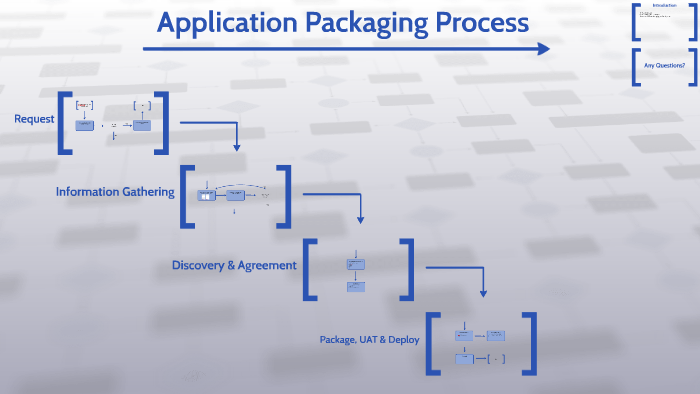

The blister packaging process flow chart typically starts with the design of the blister card and cavity, followed by material selection and forming. The next step involves filling the cavities with the product, sealing the blister card to the cavity, and finally packaging and labeling the finished product for distribution.

Blister Packaging Process Flow Chart

Key Steps in the Blister Packaging Process

1. Design: The first step in the blister packaging process is designing the blister card and cavity to fit the product securely and showcase it effectively to consumers. The design must consider factors such as size, shape, and material compatibility.

2. Material Selection and Forming: Once the design is finalized, the next step is selecting the appropriate materials for the blister card and cavity. The materials must be compatible with the product and provide the necessary protection and visibility. The forming process involves heating the plastic sheets and shaping them into cavities using molds.

3. Filling and Sealing: After the cavities are formed, the next step is filling them with the product. This can be done manually or using automated equipment depending on the volume of production. Once the cavities are filled, the blister card is sealed to the cavity using heat or pressure to ensure the product is securely enclosed.

4. Packaging and Labeling: The final step in the blister packaging process is packaging the finished product in boxes or trays for distribution. The products are labeled with necessary information such as product name, dosage, and expiration date to comply with regulatory requirements and provide information to consumers.