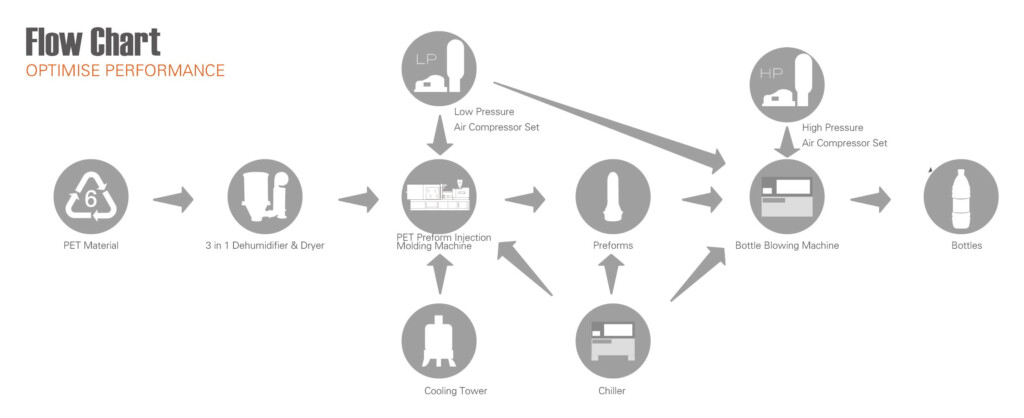

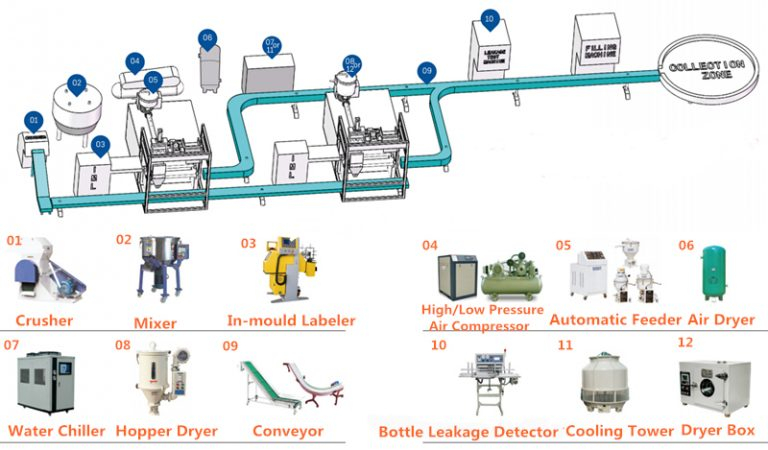

Blow moulding is a manufacturing process used to create hollow plastic parts, such as bottles and containers. The process involves melting plastic resin and then shaping it into a hollow form using air pressure. The blow moulding process flow chart outlines the various steps involved in creating a final product.

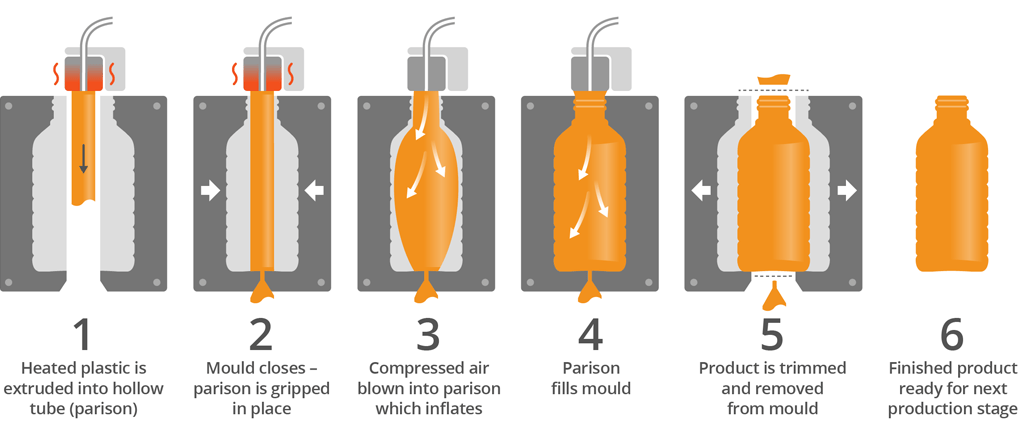

The first step in the blow moulding process is to melt the plastic resin. This can be done using a variety of methods, including extrusion or injection moulding. Once the plastic is melted, it is placed into a mould cavity, where it is shaped into the desired form. The mould is then closed, and air is injected into the cavity, causing the plastic to expand and take on the shape of the mould.

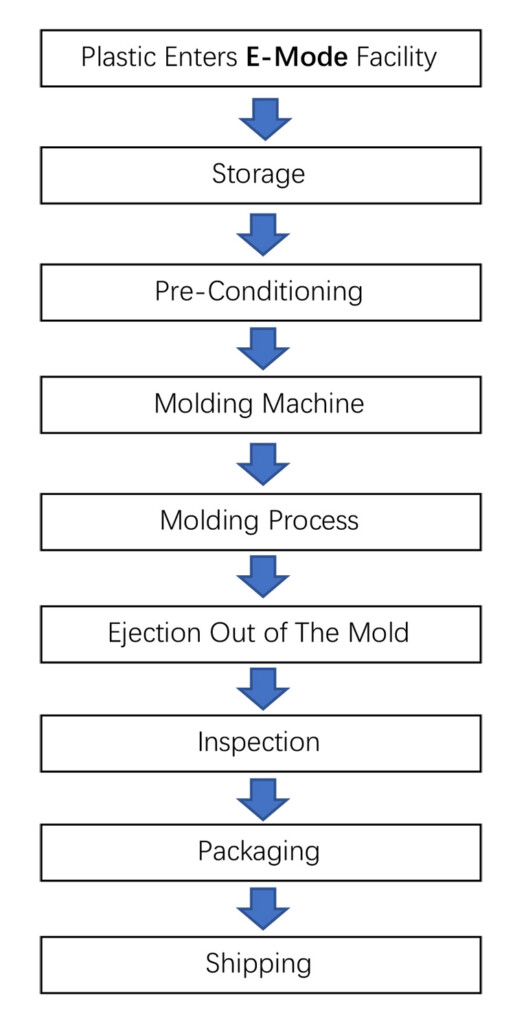

Blow Moulding Process Flow Chart

The Blow Moulding Process Flow Chart

The blow moulding process flow chart typically includes several key steps. These steps may vary depending on the specific type of blow moulding being used, but generally include the following:

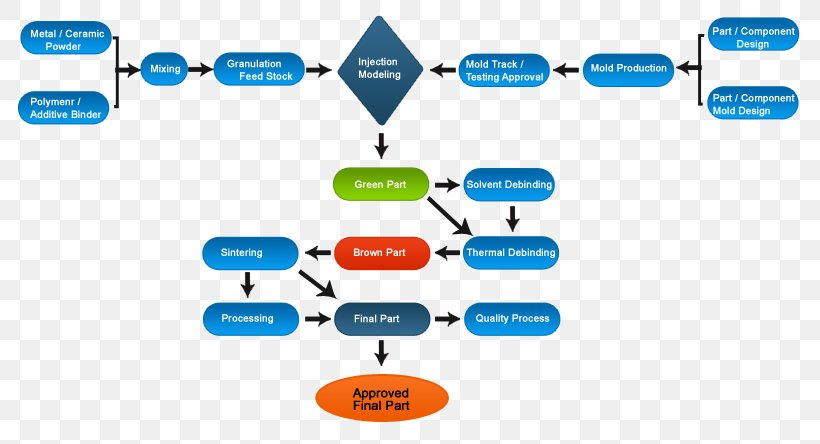

1. Material preparation: This step involves melting the plastic resin and preparing it for the moulding process.

2. Moulding: The melted plastic is injected into a mould cavity, where it is shaped into the desired form.

3. Blow moulding: Air is injected into the cavity, causing the plastic to expand and take on the shape of the mould.

4. Cooling: Once the plastic has taken on the desired shape, it is cooled to solidify the material.

5. Trim and finish: The final step involves trimming any excess material and adding finishing touches to the product, such as labeling or packaging.

Conclusion

Understanding the blow moulding process flow chart is essential for anyone involved in the manufacturing of plastic products. By following the steps outlined in the flow chart, manufacturers can create high-quality plastic parts efficiently and effectively. Whether you are a newcomer to blow moulding or a seasoned professional, having a clear understanding of the process flow chart can help you optimize your production process and achieve success in the industry.

Remember, each step in the blow moulding process is crucial to the overall success of the final product. By following the flow chart and paying close attention to detail, you can ensure that your plastic parts meet the highest standards of quality and performance.

Download Blow Moulding Process Flow Chart

Bottling Process Flow Chart Ponasa

Extrusion Blow Moulding Machine StarsPlas Is A Quality Supplier

Plastic Process Flow Chart

Injection Moulding Process Flow Chart Pdf Image To U