Harvesting of sugar cane is the first step in the brown sugar production process. The sugar cane is cut and transported to the sugar mill for extraction. At the mill, the sugar cane is crushed to extract the juice, which is then filtered to remove impurities. The juice is then heated to evaporate the water content and concentrate the sugar.

Once the sugar cane juice is concentrated, it is left to cool and crystallize. The crystals are then separated from the molasses, which is a byproduct of the sugar extraction process. The molasses can be further processed to produce other products like ethanol or animal feed.

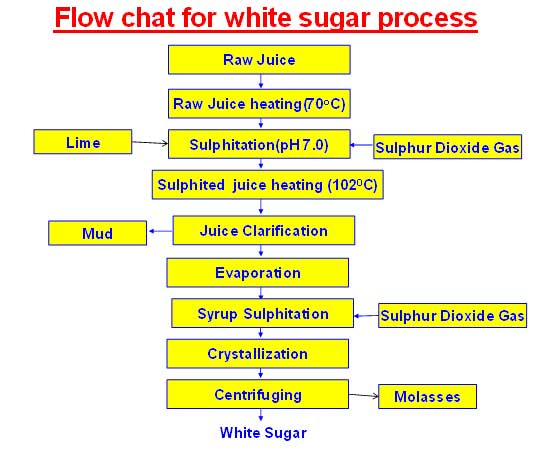

Brown Sugar Process Flow Chart

Refining and Packaging

The next step in the brown sugar process is refining the raw sugar crystals. The sugar crystals are dissolved in water and heated to form a syrup. The syrup is then filtered to remove any remaining impurities. The filtered syrup is then evaporated to form sugar crystals, which are dried and cooled.

The final step in the brown sugar production process is packaging. The brown sugar crystals are packed into bags or containers for distribution to consumers. The packaging process ensures that the brown sugar remains fresh and free from contamination. The brown sugar is then ready to be sold in stores or used in various recipes.