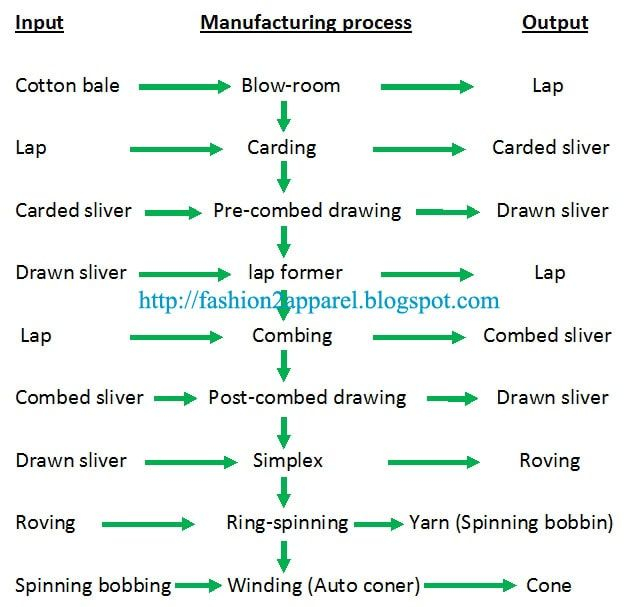

In the first step of the carpet manufacturing process, the yarn is prepared. This involves selecting the type of yarn, such as nylon, polyester, or wool, and dyeing it to the desired color. The yarn is then spun into individual strands and wound onto bobbins for further processing. The quality of the yarn is crucial to the final product’s appearance and durability.

Once the yarn is prepared, it is ready for tufting. Tufting is the process of weaving the yarn into a backing material to create the carpet’s pile. This can be done using a variety of techniques, including cut pile, loop pile, or a combination of both. The tufting process is where the carpet’s design and texture are determined, so attention to detail is essential.

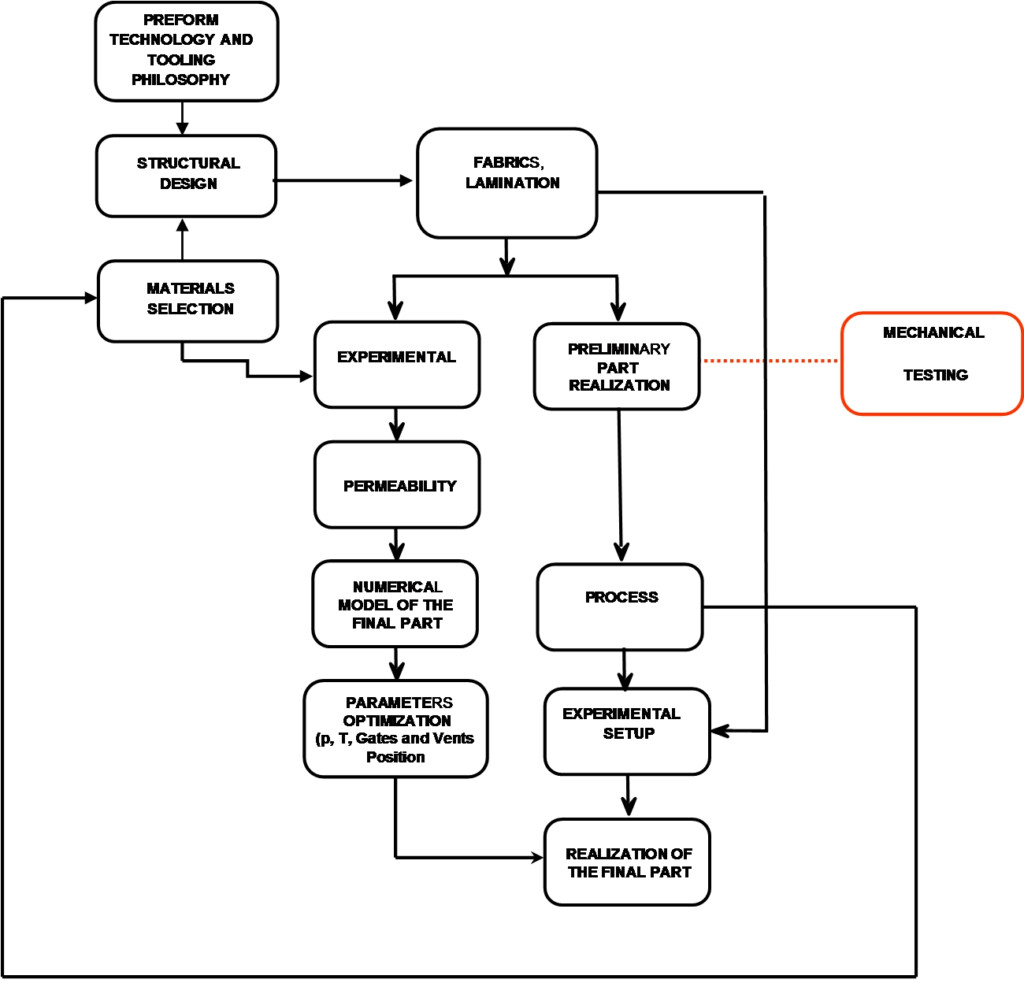

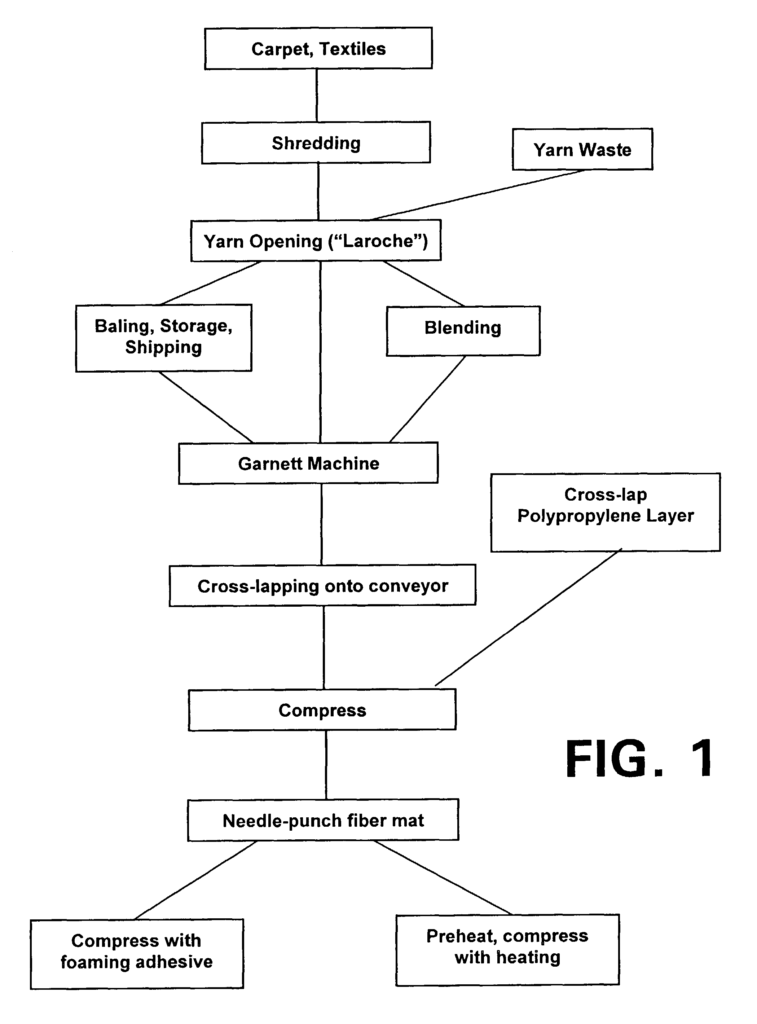

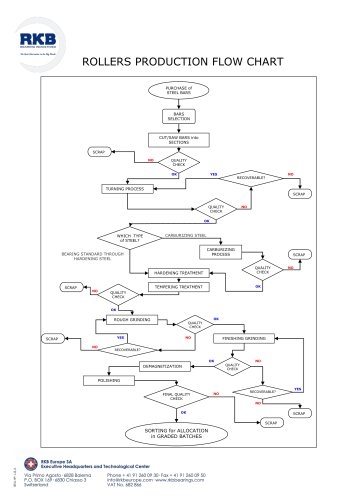

Carpet Manufacturing Process Flow Chart

2. Dyeing and Finishing

After tufting, the carpet undergoes a dyeing and finishing process to enhance its appearance and durability. The carpet is dyed using large vats of color, ensuring uniform coverage and vibrant hues. Once dyed, the carpet is treated with special finishes to protect against stains, moisture, and wear.

Finally, the carpet is inspected for quality control before being rolled and packaged for distribution. Any defects or imperfections are corrected, ensuring that only the highest quality carpets reach the market. The finished product is then shipped to retailers or customers for installation in homes, offices, or commercial spaces.

3. Installation and Maintenance

Once the carpet is installed, proper maintenance is essential to prolong its lifespan and keep it looking its best. Regular vacuuming, spot cleaning, and professional deep cleaning are all part of a comprehensive carpet care routine. By following these steps, you can enjoy your carpet for years to come.

Understanding the carpet manufacturing process flow chart can give you a greater appreciation for the craftsmanship and artistry that goes into creating these essential home furnishings. From yarn preparation to installation and maintenance, every step is carefully executed to ensure a high-quality product that adds comfort and style to any space.

Download Carpet Manufacturing Process Flow Chart

Carpet Manufacturing Process Flow Chart Carpet Vidalondon

Carpet Manufacturing Process Flow Chart Carpet Vidalondon

Carpet Manufacturing Process Flow Chart Carpet Vidalondon

Carpet Manufacturing Process Flow Chart Carpet Vidalondon