Ceramic tiles are a popular choice for flooring and wall coverings due to their durability and aesthetic appeal. The manufacturing process of ceramic tiles involves several steps, each of which plays a crucial role in producing high-quality tiles. Understanding the flow chart of the ceramic tile manufacturing process can help you appreciate the effort and craftsmanship that goes into creating these beautiful tiles.

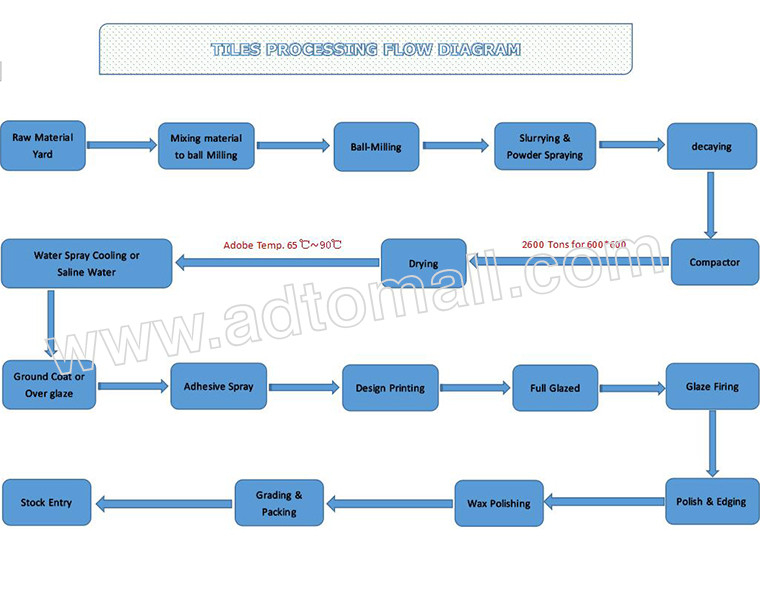

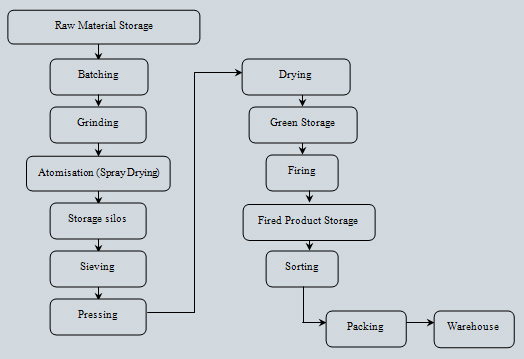

The first step in the ceramic tile manufacturing process is the preparation of raw materials. The primary raw materials used in ceramic tile production are clay, feldspar, and silica. These materials are mined, crushed, and blended to create a uniform mixture. Water is then added to the mixture to form a slurry, which is poured into molds to shape the tiles. The tiles are then dried to remove excess moisture before being fired in a kiln at high temperatures to achieve the desired hardness and durability.

Ceramic Tile Manufacturing Process Flow Chart

Glazing and Decoration

After the tiles have been fired, they are ready for glazing and decoration. Glaze is a thin layer of glass that is applied to the surface of the tiles to protect them from wear and tear and enhance their appearance. The glaze can be applied using various methods, including spraying, dipping, or pouring. Once the glaze has been applied, the tiles are fired again at a lower temperature to fuse the glaze to the surface. Decorative patterns or designs can also be added to the tiles using techniques such as screen printing or digital printing to create unique and eye-catching finishes.

Quality Control and Packaging

Once the tiles have been glazed and decorated, they undergo rigorous quality control checks to ensure that they meet industry standards for hardness, durability, and appearance. Tiles that do not meet the required criteria are discarded, while those that pass inspection are carefully packaged and prepared for distribution. The final step in the ceramic tile manufacturing process is packaging, where the tiles are stacked, wrapped, and labeled before being shipped to retailers or customers. By following a well-defined flow chart, ceramic tile manufacturers can produce high-quality tiles that meet the demands of the market and satisfy customer expectations.

By understanding the ceramic tile manufacturing process flow chart, you can gain a greater appreciation for the craftsmanship and attention to detail that goes into creating these versatile and beautiful tiles. Whether you are considering installing ceramic tiles in your home or are interested in the production process, knowing how ceramic tiles are made can help you make informed decisions and choose the best products for your needs.

Download Ceramic Tile Manufacturing Process Flow Chart

Ceramic Tile Manufacturing Process Flow Chart Ponasa

Ceramic Tile Manufacturing Process Flow Chart Ponasa

Ceramic Tile Manufacturing Process Flow Chart A Visual Reference Of

Ceramic Tile Manufacturing Process Flow Chart A Visual Reference Of