In the manufacturing industry, cold rolling is a process used to shape metal sheets into thinner gauges. The cold rolling mill process involves passing metal sheets through a series of rollers to reduce their thickness and improve their surface finish. This process is commonly used in the production of steel, aluminum, and other metals.

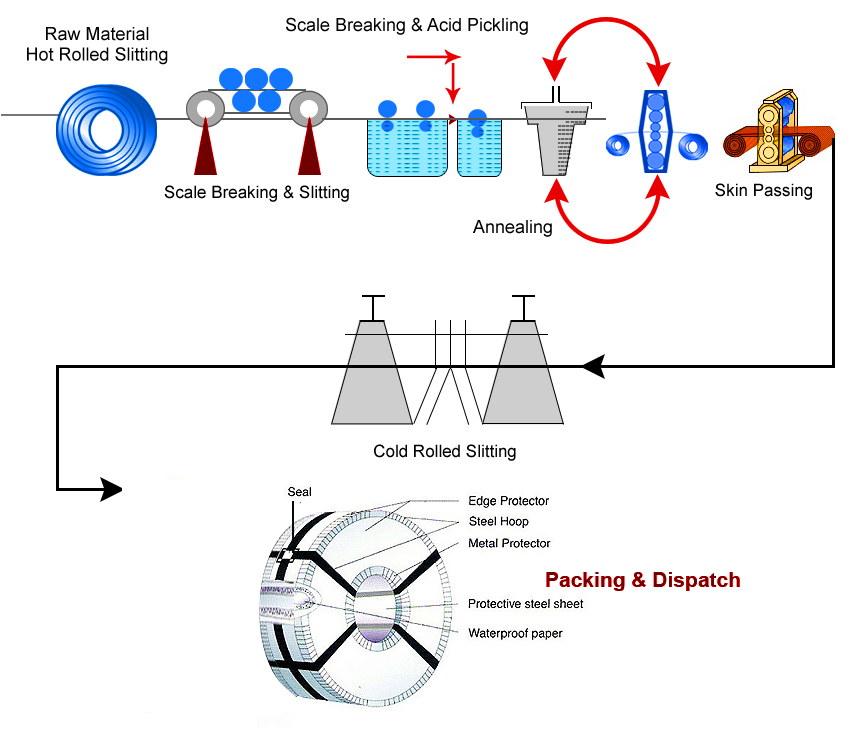

The cold rolling mill process flow chart outlines the steps involved in cold rolling and provides a visual representation of the process. Understanding this flow chart is essential for those working in the metal fabrication industry to ensure efficient and accurate production.

Cold Rolling Mill Process Flow Chart

Key Steps in Cold Rolling Mill Process Flow Chart

The cold rolling mill process flow chart typically includes the following key steps:

1. Raw material preparation: The process begins with preparing metal sheets or coils for cold rolling by cleaning and inspecting them for defects.

2. Rolling: The metal sheets are passed through a series of rollers to reduce their thickness and achieve the desired gauge. This step is critical for shaping the metal and improving its mechanical properties.

Benefits of Using a Cold Rolling Mill Process Flow Chart

Utilizing a cold rolling mill process flow chart offers several benefits, including:

1. Improved efficiency: The flow chart helps streamline the production process and identify potential bottlenecks or issues that may arise during cold rolling.

2. Enhanced quality control: By following the flow chart, manufacturers can ensure that each step in the cold rolling process is completed accurately and consistently, leading to higher-quality products.