Condensed milk is a popular dairy product that is made by evaporating most of the water content from fresh milk and adding sugar. It is commonly used in desserts, coffee, and other recipes. The process of making condensed milk involves several steps that are outlined in a flow chart to ensure consistency and quality.

The condensed milk process flow chart typically starts with receiving fresh milk from dairy farms. The milk is then pasteurized to ensure it is free from harmful bacteria. After pasteurization, the milk is concentrated by evaporating some of the water content. This concentrated milk is then mixed with sugar to achieve the desired sweetness level. The mixture is then homogenized to ensure a smooth and uniform texture. Finally, the condensed milk is cooled and packaged for distribution.

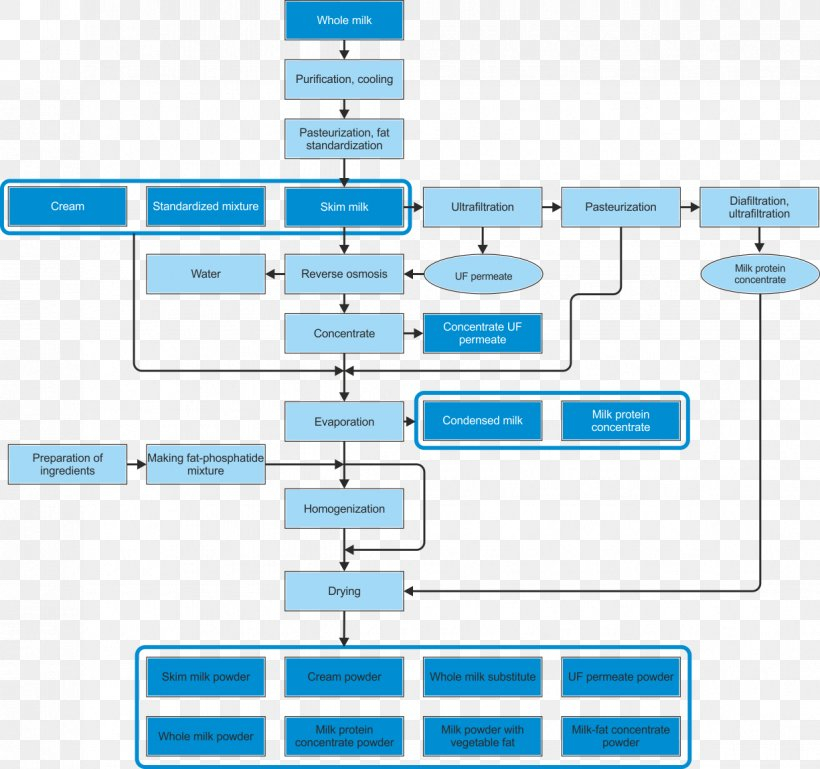

Condensed Milk Process Flow Chart

Benefits of Using a Process Flow Chart

Having a condensed milk process flow chart is essential for dairy manufacturers to ensure consistency in their product. By following the flow chart, manufacturers can maintain quality control and adhere to food safety regulations. It also helps in training new employees on the production process and troubleshooting any issues that may arise during production. Overall, a well-designed flow chart streamlines the production process and improves efficiency.