One of the first steps in cottage cheese production is milk pasteurization. This process involves heating the milk to a specific temperature to kill any harmful bacteria present. Once pasteurized, the milk is cooled down to the desired temperature before proceeding to the next step.

After pasteurization, the milk is inoculated with a starter culture, which helps kickstart the fermentation process. The culture contains specific strains of bacteria that contribute to the unique flavor and texture of cottage cheese.

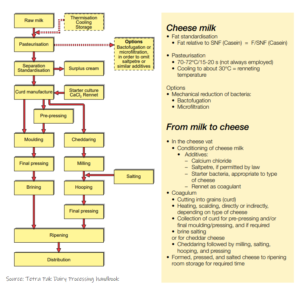

Cottage Cheese Production Flow Chart

Step 2: Coagulation and Curd Formation

After inoculation, rennet is added to the milk to initiate coagulation. Rennet is an enzyme that helps the milk proteins coagulate and form curds. The milk is left undisturbed for a set amount of time to allow the curds to form properly.

Once the curds have formed, they are cut into smaller pieces to release whey and facilitate further drainage. The curds are then cooked at a specific temperature to achieve the desired texture and moisture content in the final product.

Step 3: Draining and Packaging

After cooking, the curds are drained of excess whey using a draining table or a cheesecloth. The drained curds are then transferred to molds or containers to shape the cottage cheese. The cheese is then packaged and refrigerated for storage and distribution.

Before packaging, some producers may add cream or other ingredients to enhance the flavor and texture of the cottage cheese. Once packaged, the cottage cheese is ready to be shipped to stores and consumers for consumption.