A Crib 45 Flow Chart is a crucial tool in the manufacturing industry for optimizing production processes. It provides a visual representation of the steps involved in a specific manufacturing process, allowing manufacturers to identify bottlenecks, inefficiencies, and areas for improvement. By using a flow chart, manufacturers can streamline their operations, reduce waste, and increase productivity.

With a Crib 45 Flow Chart, manufacturers can easily track the flow of materials, resources, and information throughout the production process. This helps them identify any potential issues that may arise and take proactive measures to address them before they impact production. By analyzing the flow chart, manufacturers can make informed decisions on how to optimize their processes and improve overall efficiency.

Crib 45 Flow Chart

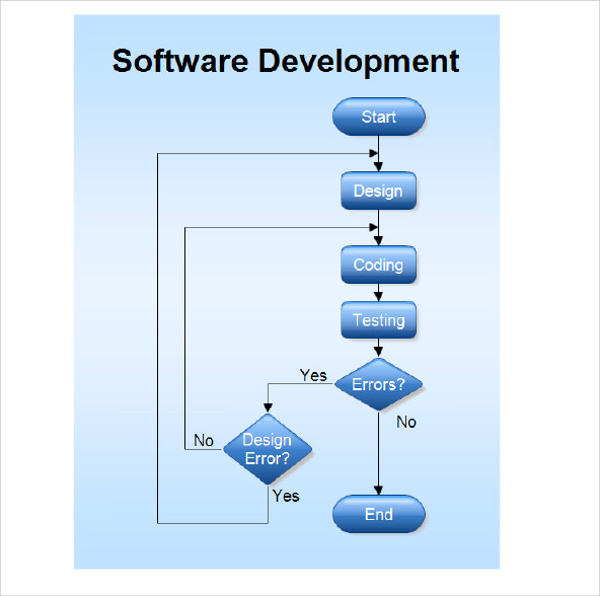

How to Create a Crib 45 Flow Chart

Creating a Crib 45 Flow Chart involves several steps to ensure accuracy and effectiveness. The first step is to identify the specific manufacturing process that needs to be charted. Once the process is identified, gather all relevant information, including materials, equipment, and personnel involved.

Next, determine the sequence of steps in the manufacturing process and create a visual representation using symbols and arrows to indicate the flow of materials and information. Be sure to include any decision points, loops, or parallel processes in the flow chart to accurately represent the production process.

Finally, review the flow chart with key stakeholders to ensure accuracy and clarity. Make any necessary revisions based on feedback and use the flow chart as a guide for optimizing the manufacturing process.