When it comes to manufacturing or production processes, having a clear and well-defined cutting process flow chart is crucial for ensuring efficiency and accuracy. This visual representation outlines the steps involved in the cutting process, from the initial design stage to the final product assembly. By having a detailed flow chart in place, companies can easily identify potential bottlenecks, optimize their workflow, and improve overall productivity.

Furthermore, a cutting process flow chart can also help in training new employees, as it provides a clear roadmap of how each step in the cutting process should be executed. This can help reduce errors and ensure consistency in the final product. Overall, investing time and effort into creating a cutting process flow chart can have a significant impact on the success of a manufacturing operation.

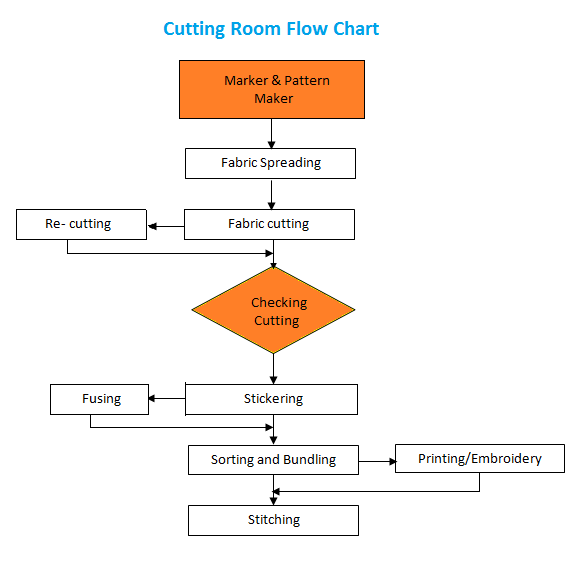

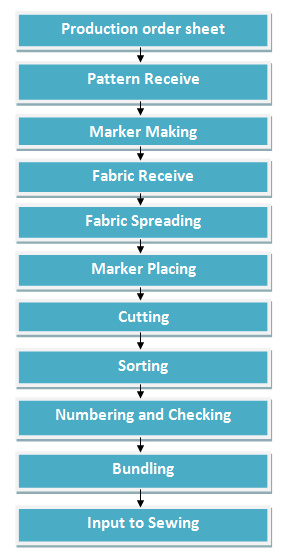

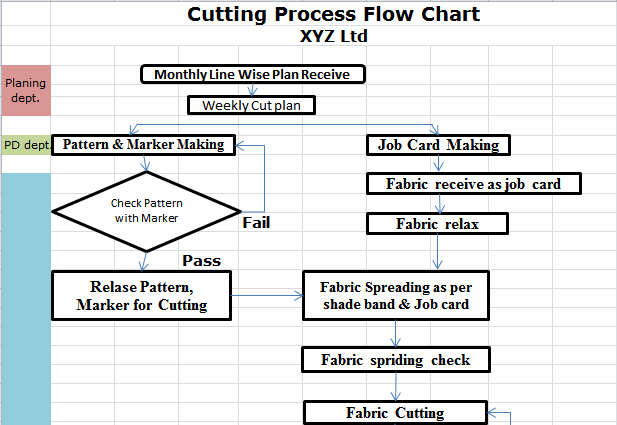

Cutting Process Flow Chart

Creating a Cutting Process Flow Chart

When creating a cutting process flow chart, it’s important to start by identifying all the key steps involved in the cutting process. This may include material selection, design, cutting, inspection, and packaging. Once these steps have been identified, they can be organized in a logical sequence to create a visual representation of the entire process.

Each step in the cutting process flow chart should be clearly defined and include relevant information such as equipment used, personnel responsible, and expected completion times. Additionally, it’s important to regularly review and update the flow chart to reflect any changes or improvements in the cutting process. By continuously refining the cutting process flow chart, companies can ensure that their manufacturing operation remains efficient and competitive in today’s fast-paced market.

Benefits of Using a Cutting Process Flow Chart

There are several benefits to using a cutting process flow chart in a manufacturing setting. One of the main advantages is that it provides a visual representation of the entire cutting process, making it easier for employees to understand and follow. This can help reduce errors and improve overall efficiency in the production process.

Additionally, a cutting process flow chart can also serve as a valuable tool for identifying areas of improvement in the cutting process. By analyzing the flow chart, companies can pinpoint bottlenecks or inefficiencies and implement solutions to streamline the cutting process. This can result in cost savings, increased productivity, and higher-quality products.

In conclusion, a cutting process flow chart is an essential tool for any manufacturing operation looking to optimize their cutting process and improve overall efficiency. By creating a clear and detailed flow chart, companies can ensure that each step in the cutting process is executed accurately and efficiently, leading to better results and increased profitability.

Download Cutting Process Flow Chart

Garment Cutting Process Flow Chart Image To U

Flow Chart Of Garments Cutting Section ORDNUR

Garment Cutting Process Flow Chart

Cosmetic Manufacturing Process Flow Chart Ppt Infoupdate