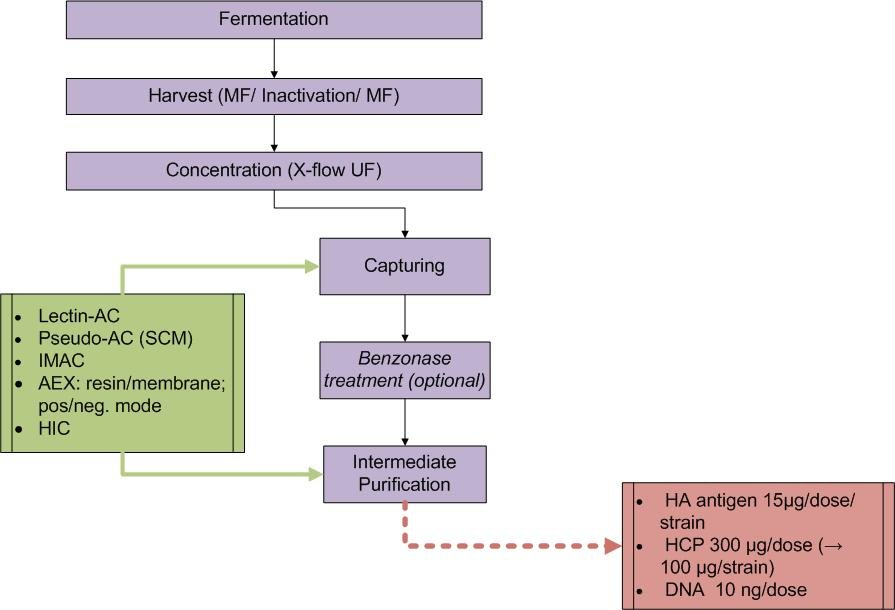

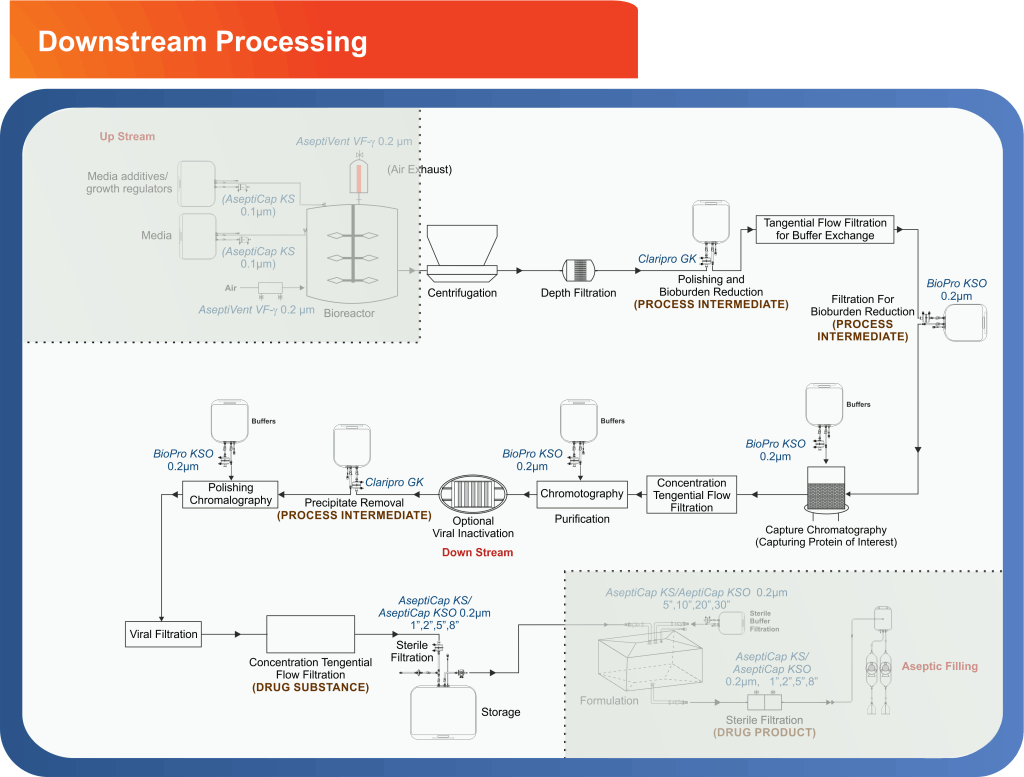

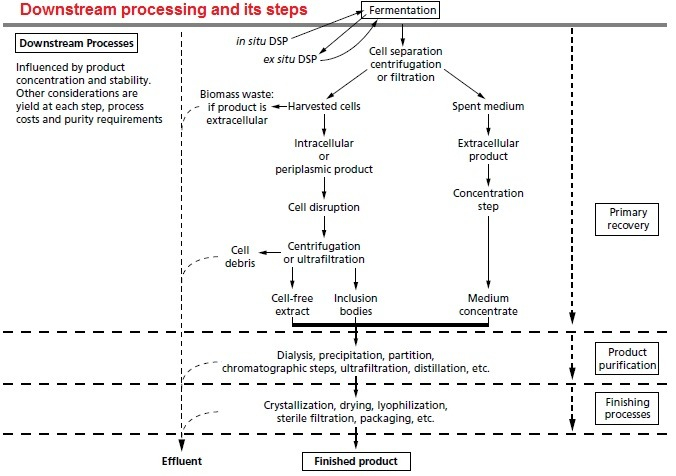

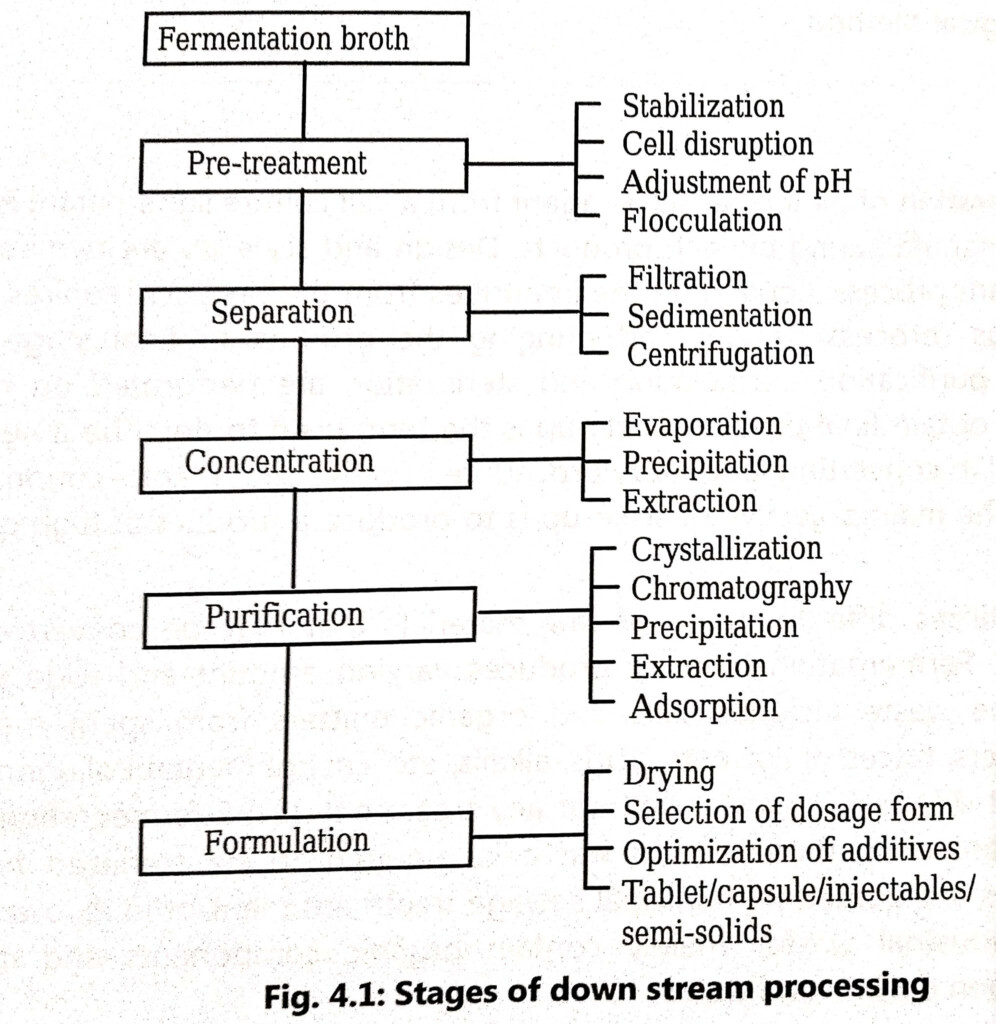

Downstream processing is a crucial step in the production of biopharmaceuticals, as it involves the purification and isolation of the desired product from the complex mixture of compounds produced during fermentation or cell culture. A well-designed downstream processing flow chart is essential for maximizing product yield, purity, and quality while minimizing costs and processing time.

There are several key steps involved in downstream processing, including cell disruption, clarification, chromatography, filtration, and formulation. Each of these steps plays a critical role in the overall purification process, and a well-planned flow chart can help ensure that each step is carried out efficiently and effectively.

Downstream Processing Flow Chart

Components of a Downstream Processing Flow Chart

When creating a downstream processing flow chart, it is important to include all the necessary components to ensure a smooth and successful purification process. The flow chart should start with the initial raw material and end with the final purified product, outlining each step in between.

Key components of a downstream processing flow chart include:

1. Cell disruption: Breaking open the cells to release the desired product.

2. Clarification: Removing cell debris and other impurities from the mixture.

3. Chromatography: Separating the desired product from other compounds based on their unique properties.

4. Filtration: Removing any remaining impurities from the product.

5. Formulation: Preparing the purified product for storage and distribution.

Optimizing Your Downstream Processing Flow Chart

To optimize your downstream processing flow chart, it is important to consider factors such as product yield, purity, and quality, as well as cost and processing time. By carefully planning each step in the purification process and identifying potential bottlenecks or inefficiencies, you can streamline the process and improve overall productivity.

Additionally, utilizing automation and advanced technologies can help increase efficiency and accuracy in downstream processing. By incorporating these tools into your flow chart, you can further enhance the purification process and achieve higher product yields and purity levels.

In conclusion, a well-designed downstream processing flow chart is essential for maximizing product yield, purity, and quality in the production of biopharmaceuticals. By including all the necessary components and optimizing the purification process, you can ensure a successful and efficient downstream processing workflow.

Download Downstream Processing Flow Chart

Downstream Processing

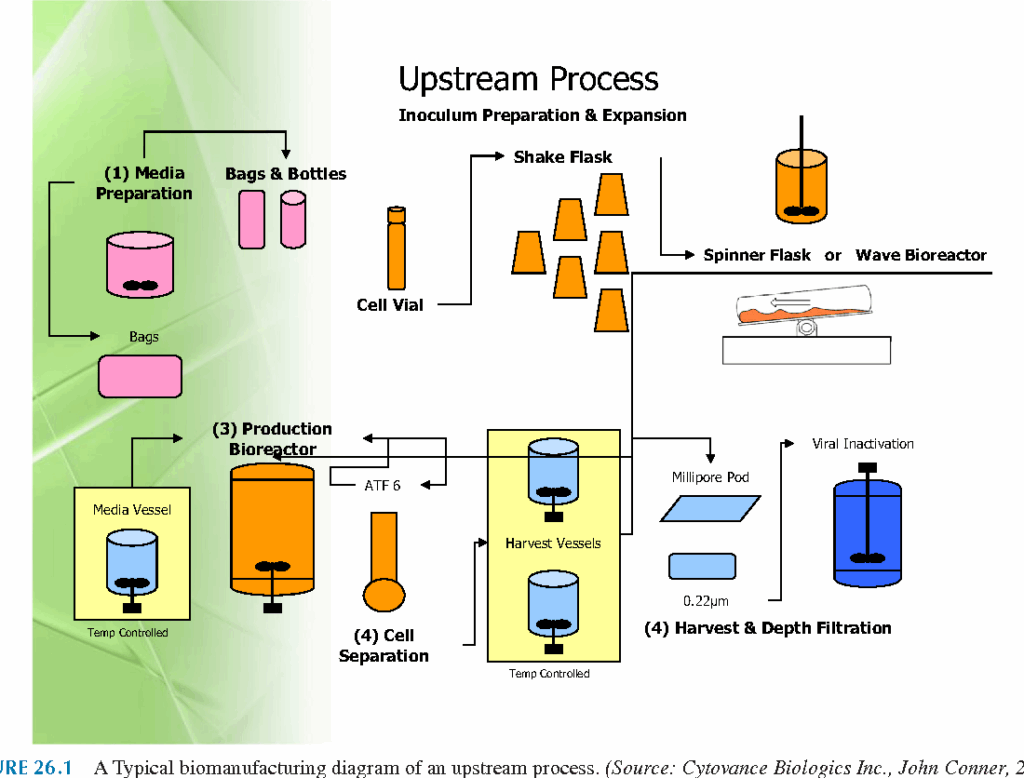

Upstream Processing Flow Chart A Visual Reference Of Charts Chart Master

Upstream Processing Flow Chart A Visual Reference Of Charts Chart Master

Downstream Processing Biology Ease