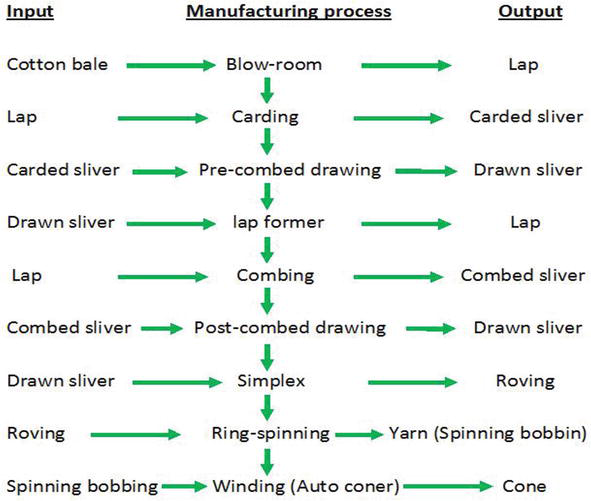

In the first step of the textile manufacturing process, raw materials such as cotton or polyester are spun into yarn. The spinning process involves pulling and twisting the fibers to create a continuous thread. This thread is then wound onto bobbins for further processing.

There are different types of spinning methods, including ring spinning, open-end spinning, and rotor spinning. Each method produces yarn with varying characteristics such as strength, thickness, and texture. Once the yarn is spun, it is ready to be dyed and woven into fabric.

Flow Chart Of Textile Manufacturing Process

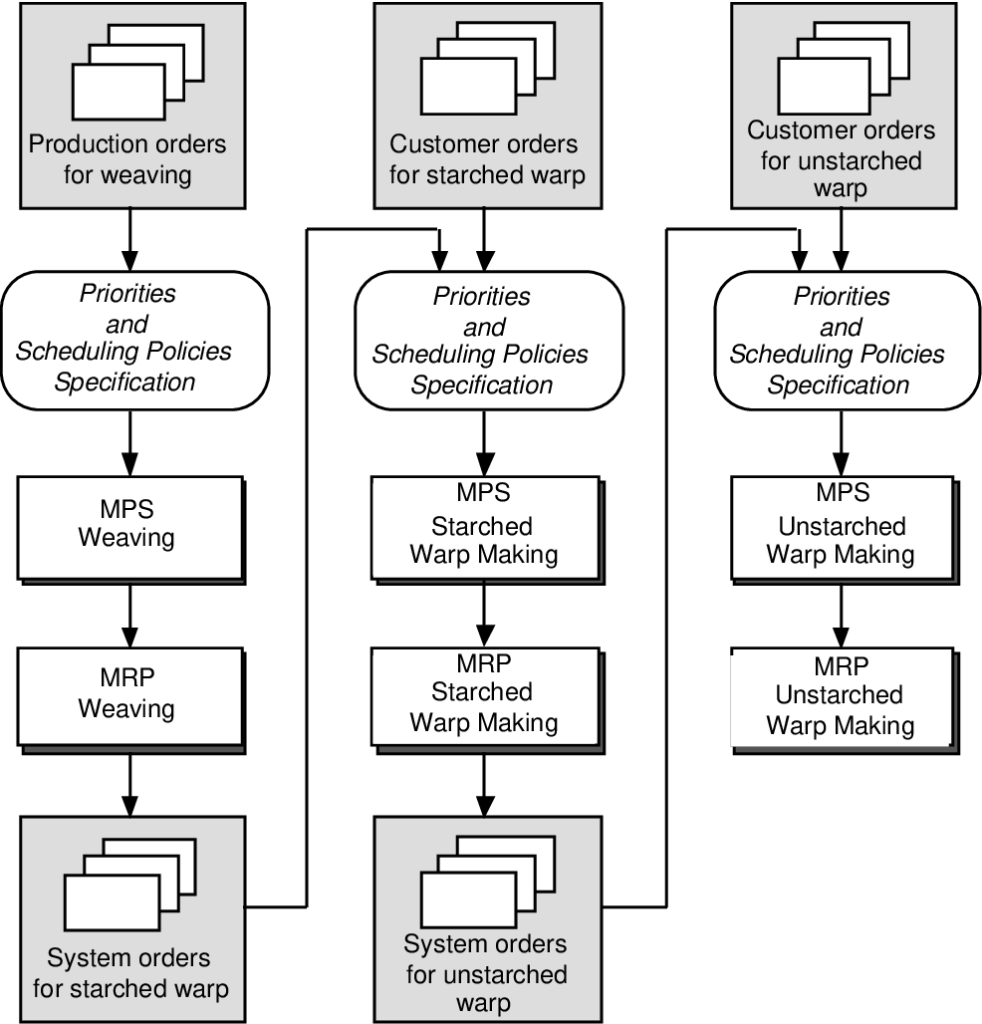

Weaving Process

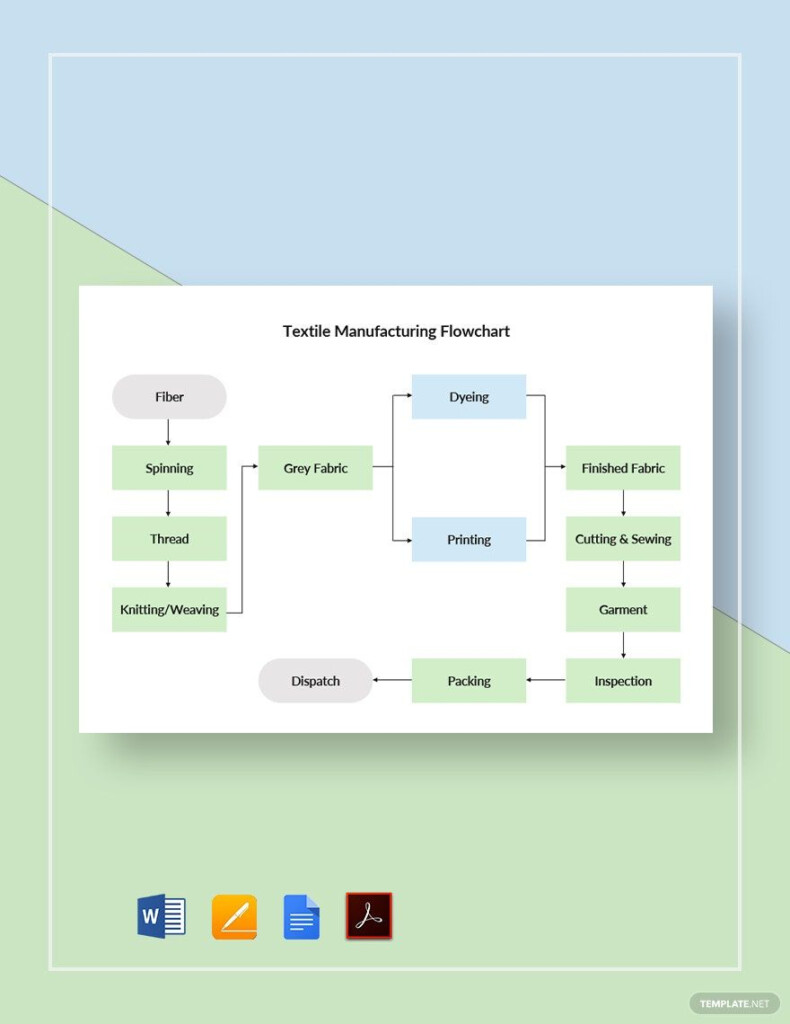

After the yarn is spun, it is dyed to the desired color and then woven into fabric. The weaving process involves interlacing the yarn on a loom to create a stable and durable fabric. There are different types of weaving patterns, such as plain weave, twill weave, and satin weave, each producing fabrics with unique textures and properties.

Once the fabric is woven, it undergoes finishing processes such as bleaching, dyeing, and printing to enhance its appearance and performance. The finished fabric is then inspected for quality and packaged for distribution to garment manufacturers and retailers.

Garment Manufacturing Process

After receiving the fabric from textile manufacturers, garment manufacturers cut and sew the fabric into finished garments. The garment manufacturing process involves pattern making, cutting, sewing, and finishing to create clothing items such as shirts, pants, dresses, and jackets.

Garment manufacturers use specialized equipment such as sewing machines, cutting tables, and pressing machines to produce high-quality garments efficiently. Once the garments are sewn and finished, they undergo quality control checks to ensure they meet industry standards before being shipped to retailers for sale.

By following the flow chart of the textile manufacturing process, companies can efficiently produce high-quality textiles and garments to meet consumer demand. Whether it’s spinning yarn, weaving fabric, or manufacturing garments, each step plays a crucial role in creating the final product.

Download Flow Chart Of Textile Manufacturing Process

Textile Manufacturing Process Textile Manufacturing F Vrogue co

Textile Manufacturing Process Textile Manufacturing F Vrogue co

Textile Manufacturing Process Flow Chart Ponasa NBKomputer

Textile Manufacturing Process Flow Chart