When it comes to managing equipment in an industrial setting, having a clear understanding of the status of each piece of equipment is crucial. An Inop Equipment Flow Chart provides a visual representation of the workflow of inoperative equipment, helping to streamline maintenance processes and minimize downtime. By clearly outlining which equipment is inoperable, the reasons for its downtime, and the steps needed to bring it back online, this chart can greatly improve efficiency and productivity in a facility.

With an Inop Equipment Flow Chart, maintenance teams can quickly identify which pieces of equipment need attention, prioritize their tasks, and track the progress of repairs. This not only helps to prevent equipment failures but also allows for better planning and allocation of resources. By having a centralized document that outlines the status of all inoperative equipment, teams can work together more effectively to ensure that downtime is minimized and operations run smoothly.

Inop Equipment Flow Chart

Creating an Effective Inop Equipment Flow Chart

When creating an Inop Equipment Flow Chart, it is important to include key information such as the equipment ID, the reason for downtime, the assigned technician, and the expected completion date. This information should be updated regularly to ensure that the chart remains accurate and up-to-date. Additionally, color-coding or symbols can be used to quickly convey the status of each piece of equipment, making it easy for teams to understand at a glance which items need attention.

By implementing an Inop Equipment Flow Chart, facilities can improve their maintenance processes, increase equipment uptime, and ultimately enhance productivity. With a clear understanding of which equipment is inoperable and the steps needed to bring it back online, maintenance teams can work more efficiently and effectively, leading to a more streamlined operation overall.

Conclusion

In conclusion, an Inop Equipment Flow Chart is a valuable tool for managing equipment in an industrial setting. By providing a visual representation of inoperative equipment and outlining the necessary steps for repair, this chart can help to streamline maintenance processes, minimize downtime, and improve overall efficiency. By implementing an Inop Equipment Flow Chart, facilities can enhance their maintenance practices, increase equipment uptime, and ultimately boost productivity.

Download Inop Equipment Flow Chart

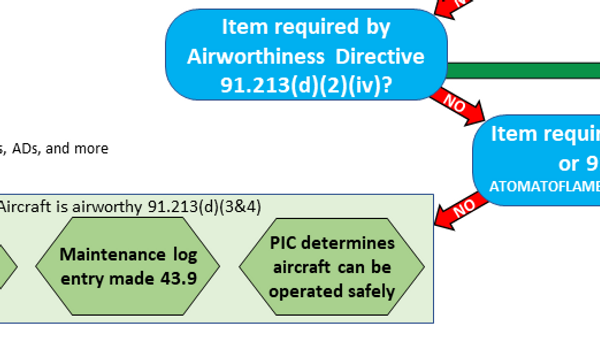

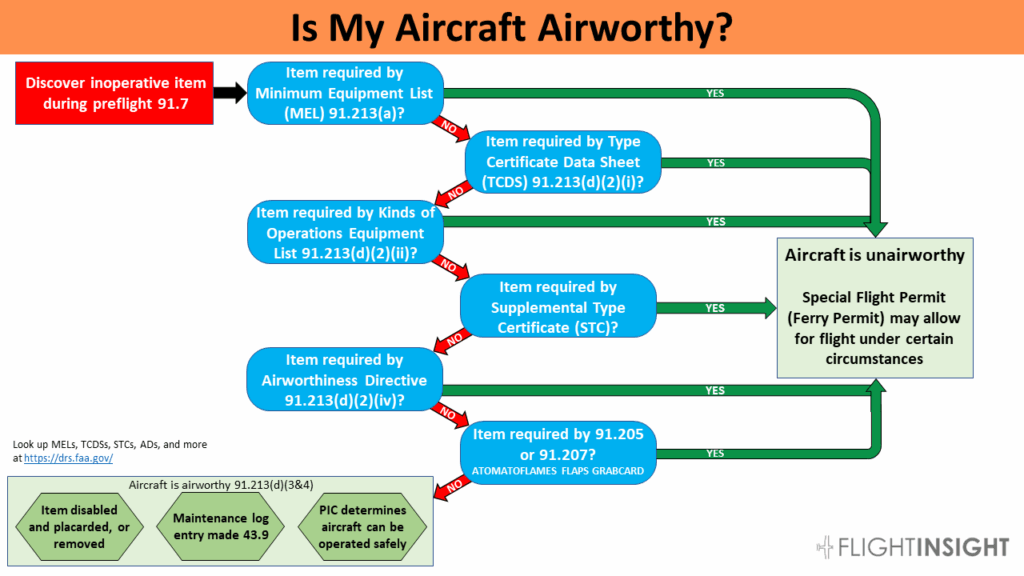

Inop Equipment List FlightInsight

Inop Equipment List FlightInsight

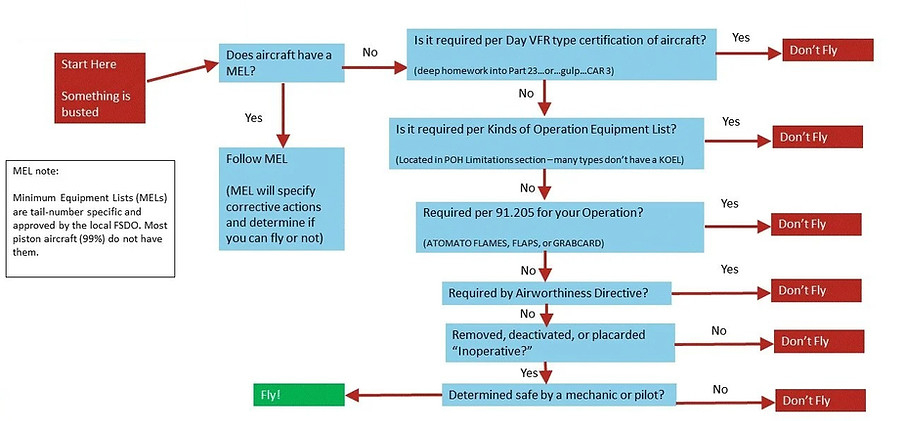

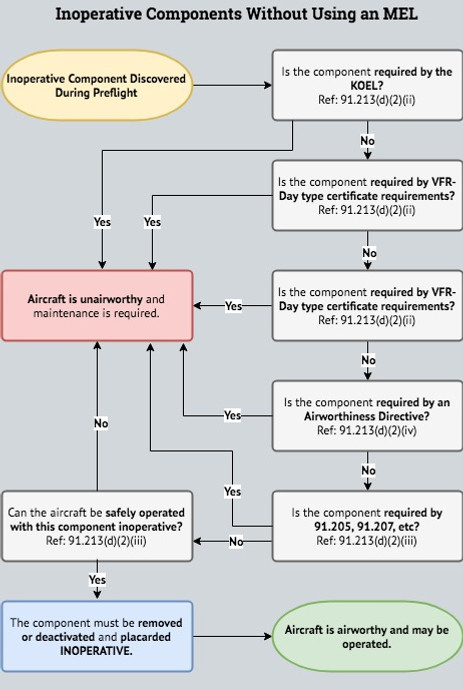

INOP Flow Chart Pilot Navigator

INOP Flow Chart Pilot Navigator