Manufacturing Process Flow Chart

Manufacturing Process Flow Chart: A Comprehensive Guide

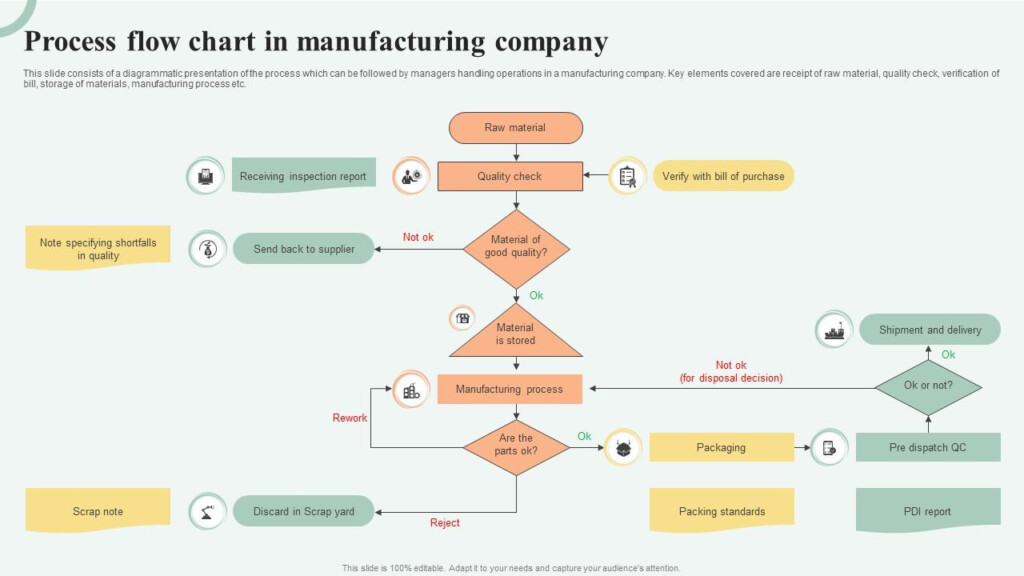

When it comes to manufacturing, having a clear and well-defined process flow chart is essential for optimizing efficiency and ensuring quality control. A manufacturing process flow chart is a visual representation of the steps involved in producing a product, from raw materials to the finished product. In this article, we will explore the key components of a manufacturing process flow chart and how it can benefit your production process.

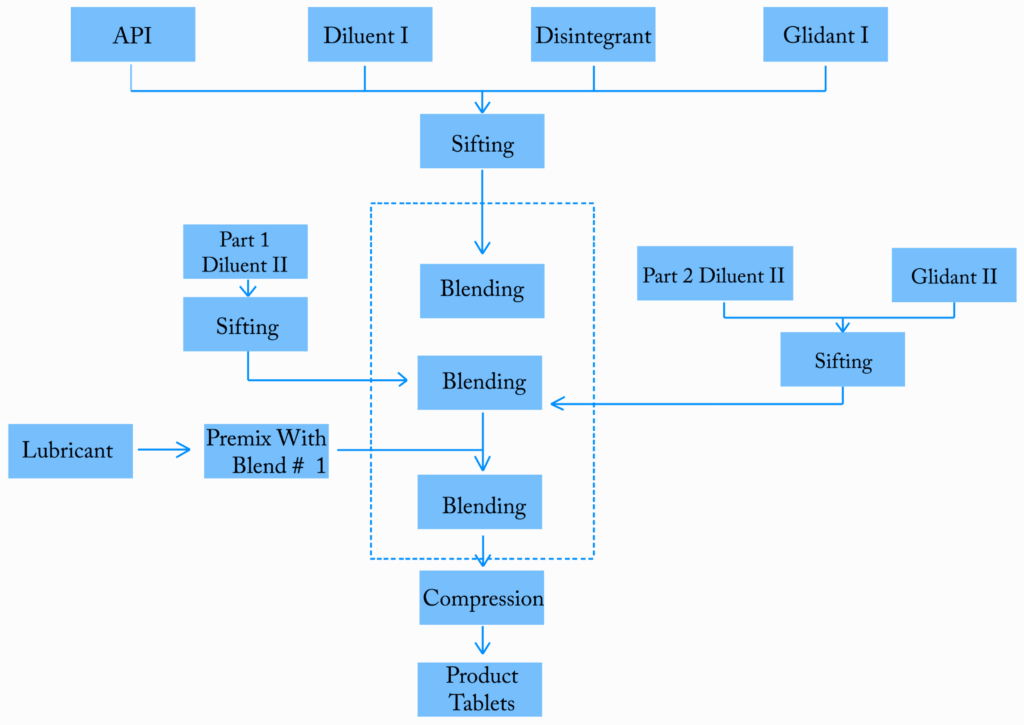

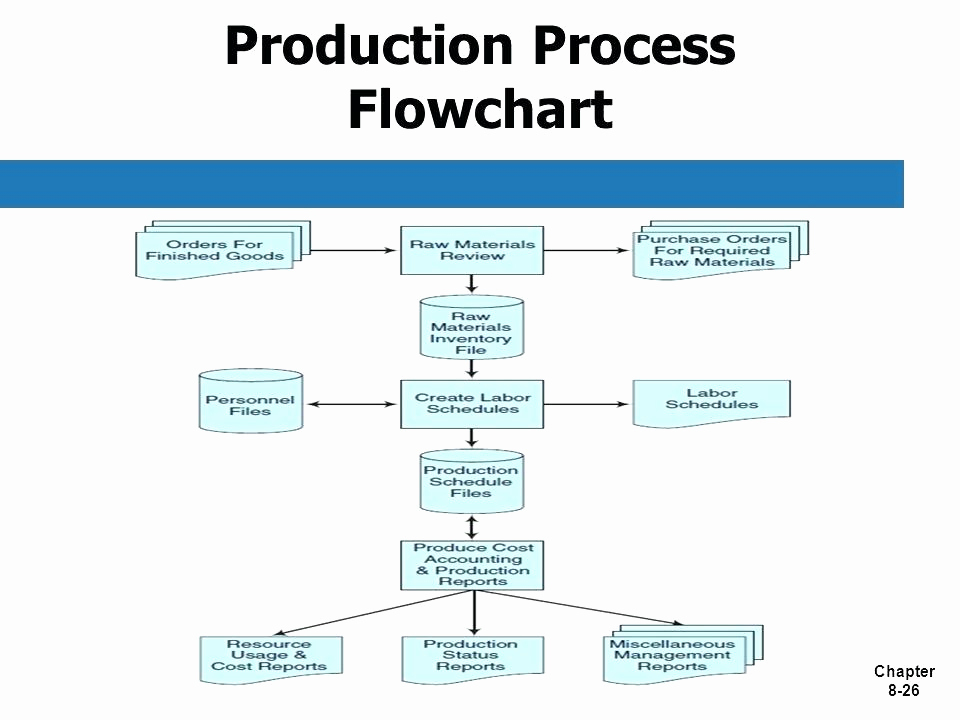

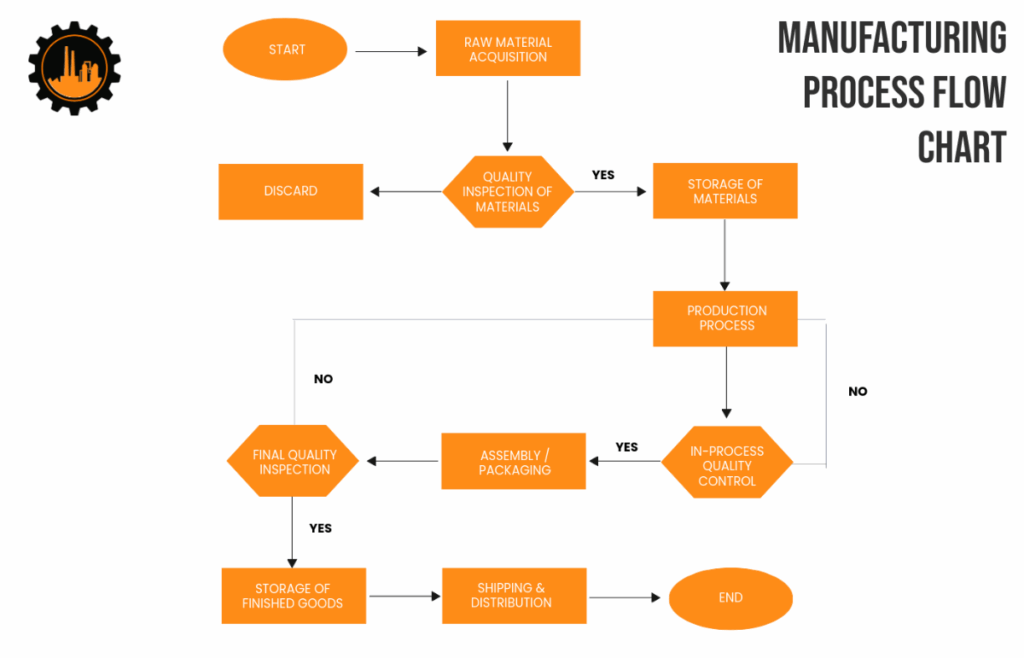

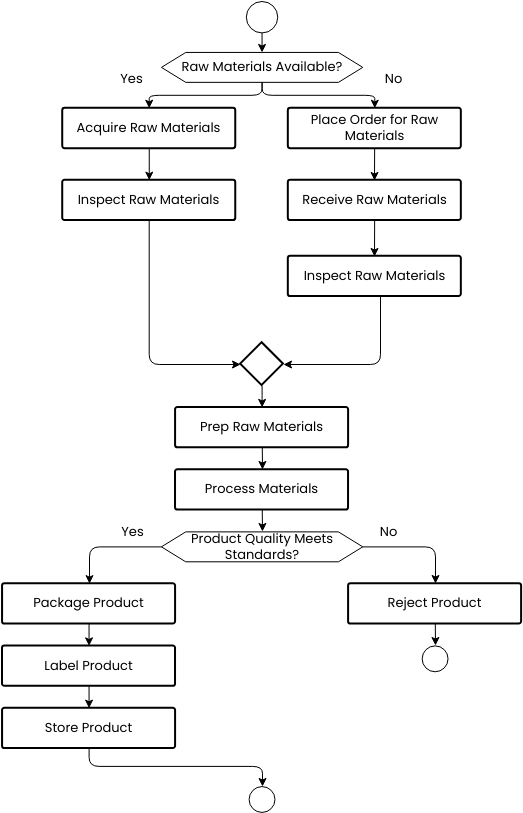

Creating a manufacturing process flow chart starts with identifying the key steps involved in the production process. This may include sourcing raw materials, manufacturing components, assembly, testing, and packaging. Each step is outlined in sequential order, with arrows indicating the flow of materials and information throughout the process. By visually mapping out the entire production process, you can identify potential bottlenecks, streamline operations, and improve overall efficiency.

The first step in creating a manufacturing process flow chart is to gather input from all stakeholders involved in the production process. This may include engineers, designers, production managers, and quality control personnel. By involving all key players in the process, you can ensure that the flow chart accurately reflects the actual production process and incorporates valuable insights from each department.

Once the key steps have been identified, the next step is to create a visual representation of the manufacturing process flow chart. This can be done using software tools such as Microsoft Visio or Lucidchart, which allow you to easily create flowcharts with drag-and-drop functionality. The flow chart should include detailed information about each step, including the resources required, estimated time for completion, and quality control checkpoints.

Implementing a manufacturing process flow chart can have a number of benefits for your production process. By visually mapping out the entire production process, you can identify potential bottlenecks and inefficiencies, allowing you to make targeted improvements to streamline operations and increase overall productivity. Additionally, a manufacturing process flow chart can serve as a valuable training tool for new employees, helping them understand the sequence of steps involved in producing a product and the role they play in the overall process.

In conclusion, a manufacturing process flow chart is an essential tool for optimizing efficiency and ensuring quality control in the production process. By creating a visual representation of the steps involved in producing a product, you can identify potential bottlenecks, streamline operations, and improve overall efficiency. Whether you are a small-scale manufacturer or a large-scale production facility, implementing a manufacturing process flow chart can help you achieve your production goals and deliver high-quality products to your customers.

Download Manufacturing Process Flow Chart

Manufacturing Process Flow Chart 30 Manufacturing Process Flow Chart

Lipstick Manufacturing Process Flow Chart Pdf Free Infoupdate

Lipstick Manufacturing Process Flow Chart Template Infoupdate

Cosmetic Manufacturing Process Flow Chart Ppt Infoupdate